To keep mechanical seal systems functioning as long as possible, we recommend using standardized seal piping plans. Detailed API seal piping plans ensure minimal seal face wear by maintaining the optimal seal chamber environment.

Since they were first formulated, seal piping plans have been maintained and remodeled by the American Petroleum Institute (API). Current plans are based on API 682 and are sorted numerically. In some cases, designated letters are also used to differentiate between plans.

Filter Plan Types

API Plan 01

Internal recirculation from pump discharge to the seal chamber.

API Plan 02

Dead-ended seal chamber with no recirculation of fluid and optional cooling/heating jacket.

API Plan 03

Open-ended or tapered seal chamber.

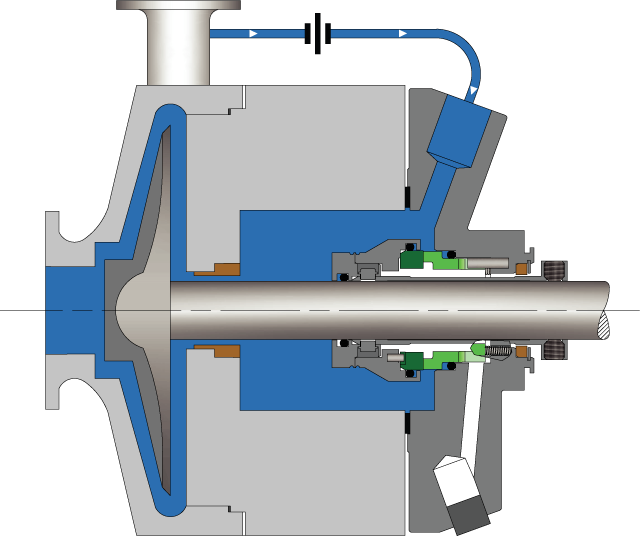

API Plan 11

Recirculation from pump discharge through a flow control orifice to the seal chamber.

API Plan 12

Recirculation from pump discharge through a strainer and flow control orifice to the seal chamber.

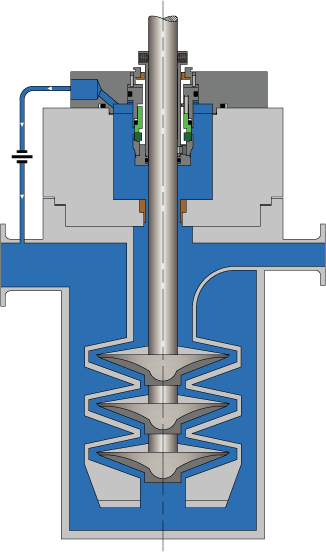

API Plan 13

Recirculation from the seal chamber through a flow control orifice to pump suction.

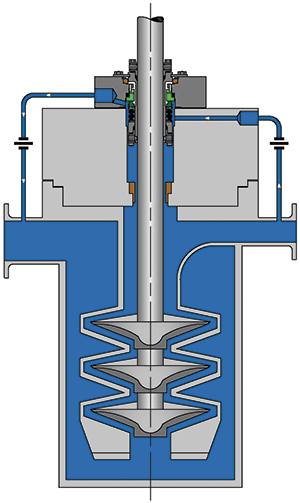

API Plan 14

Recirculation from pump discharge through a flow control orifice to the seal chamber and from the seal chamber through a flow control orifice to pump suction.

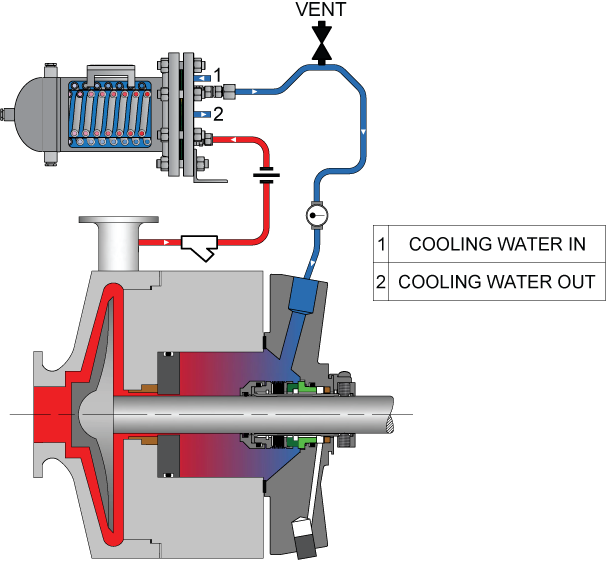

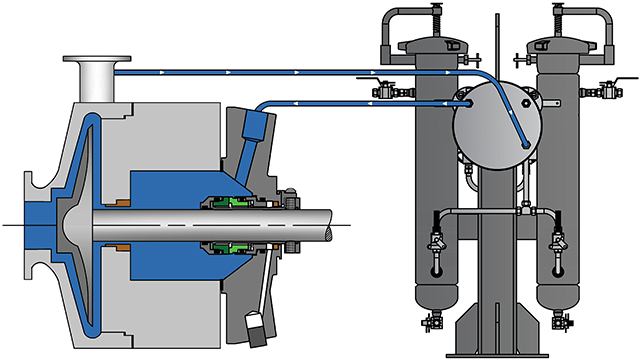

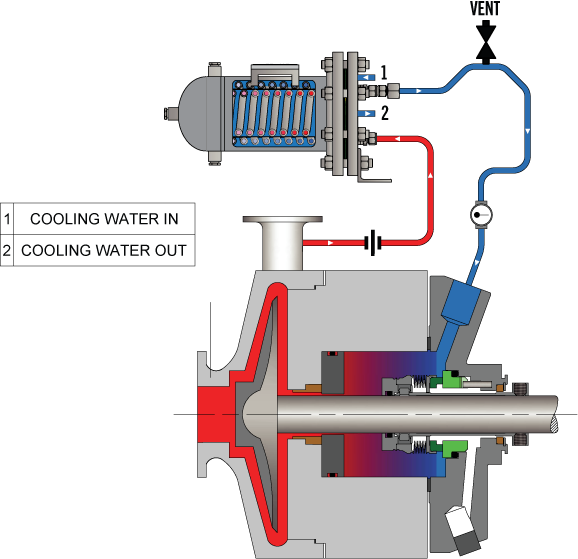

API Plan 21

Recirculation from pump discharge through a flow control orifice and cooler to the seal chamber.

API Plan 22

Recirculation from pump discharge through a strainer, flow control orifice, and cooler to the seal chamber.