Eliminates Particulates in Mechanical Seal Flush System and Improves Reliability

When an external source of clean fluid is not available or economical to use for a seal flush plan, a Flexaseal Cyclone Separator may be the answer. Cyclone separators efficiently remove abrasive media from a pump’s discharge, circulating the resulting clean fluid back into the seal chamber to cool the seal faces.

The simple construction of the Flexaseal Cyclone Separator utilizes a one-piece pressure casing, eliminating the temperature and pressure constraints imposed by bolted and gasketed casing cover designs.

When properly installed, the FAS Cyclone Separator provides lower pipe stress when inline mounted, improves circulation, and reduces temperature at the seal faces, all while offering operating pressures up to 3000 psi / 207 bar.

Features

How a cyclone separator operates is affected by many factors, and the following process should be used as a selection guideline.

- Determine the maximum and minimum acceptable clean circulation flow rates using the seal manufacturer’s information.

- Establish the required total capacity of the cyclone separator using the following formula:

Clean Flow Rate x 1.4 = Total Capacity (GPM or LPM) - Calculate available differential pressure using the following formula:

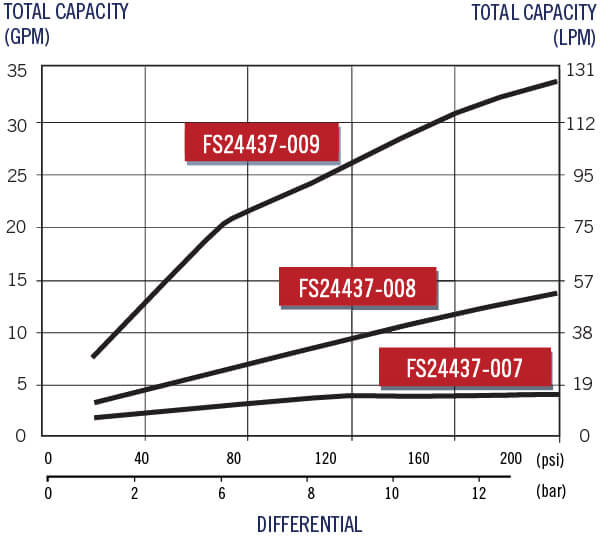

Pump Discharge Pressure – Stuffing Box Pressure = Differential Pressure - On the chart above, locate the intersection of the lines corresponding to total capacity and differential pressure. Choose the cyclone separator model with a flow rate greater than the required minimum.

Downloads

For more information on our Cyclone Separator

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.