Mechanical Seals Designed and Engineered to Handle Demanding Operating Environments

There is no one universal seal for all mixer applications. Every mixer, agitator, and reactor model is distinctive and engineered for a specific application. Many of these applications require seals to perform in environments that would destroy common seals due to extreme drag and shear forces, abrasive materials, or other challenges. That means successful sealing requires clearly defining the type of equipment, the product, and the sealing conditions. Flexaseal’s design and engineer team are capable of providing innovative solutions for your toughest challenges.

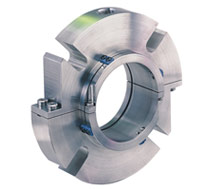

85M

Fully Split Cartridge Mechanical Seal for Mixers and Agitators

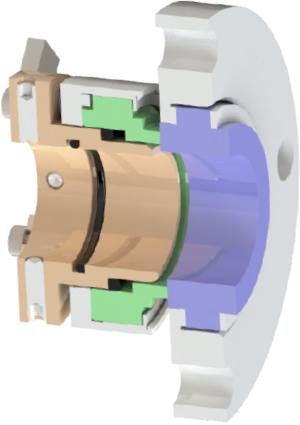

23M

Dry-Running Multi-Spring Component Seal for Top Entry Mixers & Agitators

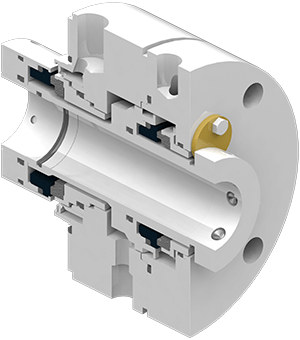

RB

Single Rotating Welded Metal Bellows Cartridge Mechanical Seal

79

Dual Tandem Stationary Multi Spring Cartridge Mechanical Seal

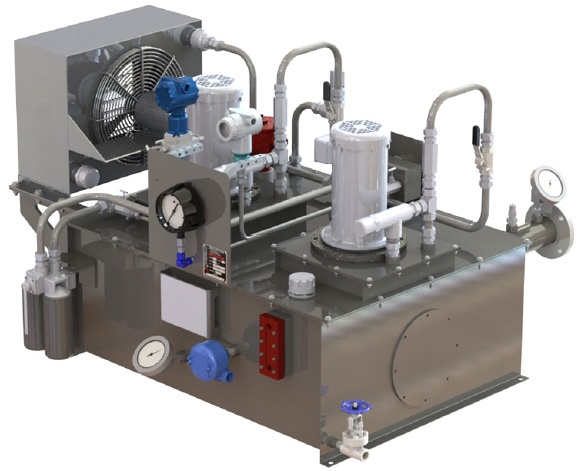

Barrier Fluid Reservoir – API Plan 53

Lube Oil Systems (MP600 Series)

Mixer Seal Repair

Quick Contact

For general inquiries, sales or quotes.