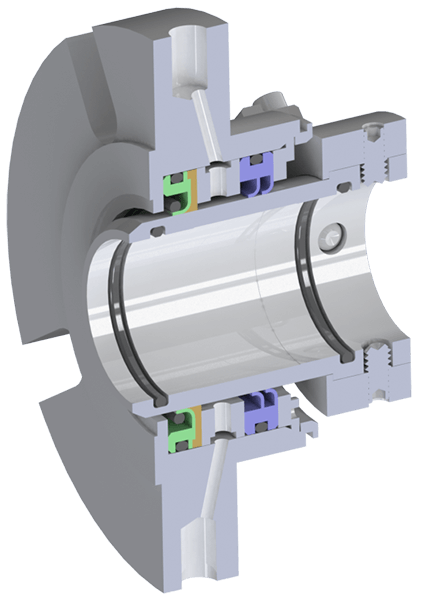

Mechanical Seal Style MLC3

Multi-Lip Cartridge Seal For Challenging Applications

For Challenging Applications

Viscous substances like syrups, tars, oils, resins, and glues can often cause problems for regular mechanical seals. Until now, simple lip seal designs have been the preferred choice for dealing with these substances, which are far thicker than what most mechanical seals are designed to handle. Flexaseal’s MLC3 multi-lip cartridge seal combines the best of both technologies, bringing you a game-changing solution.

Our MLC3 cartridge seal gets the job done more effectively, sealing across a broad range of speeds with longer life in service compared to other products. As an added benefit, the MLC3 requires virtually no seal support system, saving you time and effort.

Mechanical Seal Style MLC3

Design Features & Benefits

Why the MLC3?

- Non-clogging, proprietary engineered lip seals resist shearing and provide a reliable seal over the integrated hard-coated shaft sleeve.

- Anti-rotation rings in the lip seals provide exceptional static sealing ability.

- Energized O-ring maintains a seal and prevents leakage with viscosity changes in the process.

- Proprietary lip seal material, PTFE-ML, is not only suited for aggressive chemicals and viscous abrasives, but also complies with GMP, FDA, and EU standards.

- Easy to install cartridge design for quick and simple fit-ups.

- Field repairs are simplified with readily-available spare parts kits.

Our PTFE-ML seal can tolerate:

| Axial movement: | ±.125” |

| Max. runout: | ±.020″ TIR (Typical) ±.025″ TIR (Low speeds) |

| Vacuum: | 25mm Hg |

Specifications

Materials of Construction

| Lip Seals: | PTFE-ML proprietary compound |

| Sleeve: | Hard Coated 316 SS Sintered Silicon Carbide upon request |

| Elastomers: | FKM standard Other materials upon request |

| Lantern Ring: | PTFE |

| Metallurgy: | 316 SS |

| Also available: | FDA-approved materials of construction Energized O-ring or garter spring options |

Operating Parameters

| Viscosities: | up to 500,000 cps |

| Process Pressures: | up to 300 psig (20.7 bar) |

| Temperatures with environmental control: | -100° to 450°F (-73.3 to -267.7°C) |

| Surfaces Speeds | Dry-running: 3000 fpm (15.24 m/s) w/ environmental control: 5000 fpm (25.4 m/s) |

Maximum viscosity/temperatures/speed/pressure indicates operating extremes independently and does not imply the seal will function at these extremes at the same time.

Downloads

For more information on the RKCS

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

Additional MLC3 Seal Configurations

Seals can be grease packed with Magnalube®-G or Molykote™111 Dual Seal or Vacuum upon request.

Tandem configuration with Lubricant or Purge.

Dual Seal or Vacuum configuration with Barrier / Buffer Fluid.