When one is posed with the need to provide a Mechanical Seal Filtration System, there are many elements that need to be considered. The obvious question is: what needs to be removed from the seal flush stream? We will address particulates and water removal with this tutorial.

The need for filtration comes to light with poor seal performance, usually described as excessive leakage. The root cause is easily determined once the seal is removed and examined. In most cases the seal is packed with the offending particulate matter. Other signs of premature wear are phonograph grooving of the Primary and Stationary seal faces, caused as the particulates cross the faces.

Mechanical seals require a clean environment if they are to perform to their required service life. There are many seal designs and materials on the market today which have very different seal flush requirements. These designs range from flush rates of two gpm to upwards of twenty gpm.

The process medium will help in determining the seal face design, which usually dictates the required seal flush rate. The flush rate will also be a factor in determining the size of the filter. The comparison of the filter element surface area to the amount of flow traveling across it, is known as the Mass Flux; i.e., Mass flow per unit area. The lower your Mass Flux number (flush rate divided by surface area) the longer your service life of the filter element.

This will also decrease the differential pressure across the filter element, which helps to build the filtered cake (particles on the filter element) without compressing the particulate gains too tightly. Select a filtration system with a Mass Flux number less than 1.0.

The filter element material has a great impact on the efficiency of the filter element to remove particles of a given size; e.g., 3 micron rated element, absolute or nominal. A nominal rated element will remove 60 to 98% of the rated pore size. Generally, these are cellulose media elements with low Beta Ratio numbers.

Beta ratios are the most common method of selecting a filter element. The ratio is defined as the particle count upstream divided by the particle count downstream, at the rated particle size (ex- ample – 3 micron filter). The efficiency of the filter can be calculated directly from the beta ratio because the percent capture efficiency is ((beta-1)/beta) x 100. The higher the efficiency, the higher the beta ratio number.

Borosilicate microfiber media is an excellent choice for a filter element because no other element works as efficiently or gathers as many particles as Borosilicate, with a beta ratio of 5000, 99.98% efficient.

Designing a filtration system for your application can be broken down into the following categories:

- Particulate or Coalescing Filter Element – Material, Beat Ratio, Max Flux

- Instrumentation and Flow Control Options – Filter Element DP, Flow Meters

Globe Valves, Orifice, Pressure Gauges - Operating System – Control Seal Flush Rate, Ease of Filter Element Change, Availability of spare elements and system components

The cost of a poorly designed and inadequate system for your mechanical seals quickly reveals itself with the frequent demand to change filters, due to high differential pressure across the filter element, fouled filters. This manifests into operation overtime and material cost for replacement elements, which quickly gets a lot of attention. Usually negative attention.

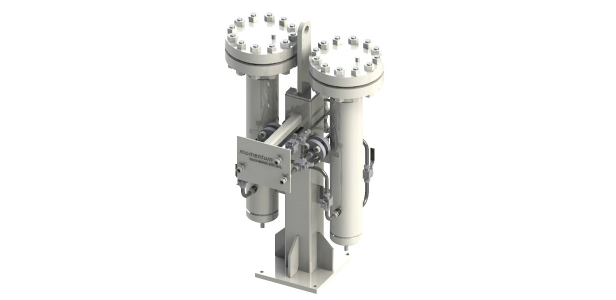

Flexaseal has engineered a very successful filtration system which addresses all the selection criteria and has been field proven with customer testing and replacing Seal Manufacturer’s OEM systems.