To keep mechanical seal systems functioning as long as possible, we recommend using standardized seal piping plans. Detailed API seal piping plans ensure minimal seal face wear by maintaining the optimal seal chamber environment.

Since they were first formulated, seal piping plans have been maintained and remodeled by the American Petroleum Institute (API). Current plans are based on API 682 and are sorted numerically. In some cases, designated letters are also used to differentiate between plans.

Filter Plan Types

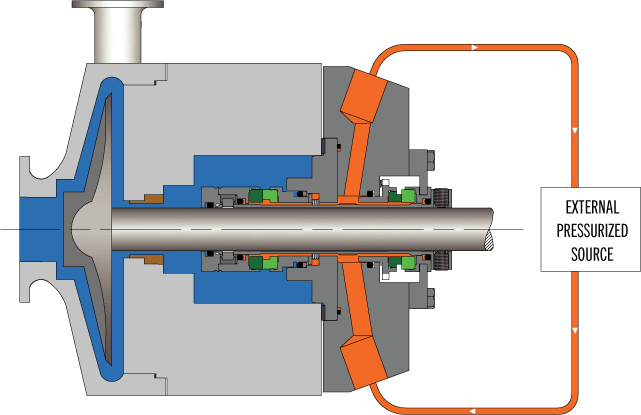

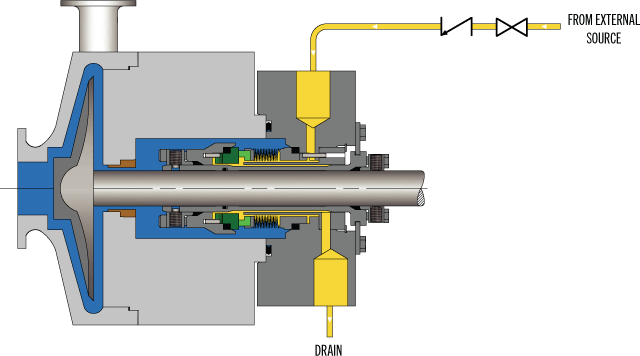

API Plan 54

Pressurized external barrier liquid system supplying clean fluid to the inboard and outboard seal faces.

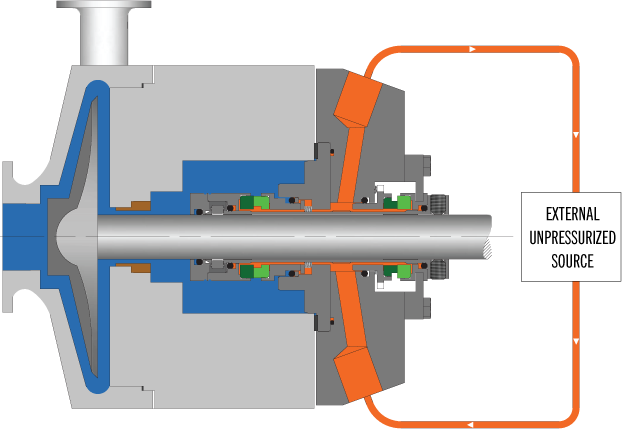

API Plan 55

Unpressurized external buffer liquid system supplying clean fluid to the inboard and outboard seal faces.

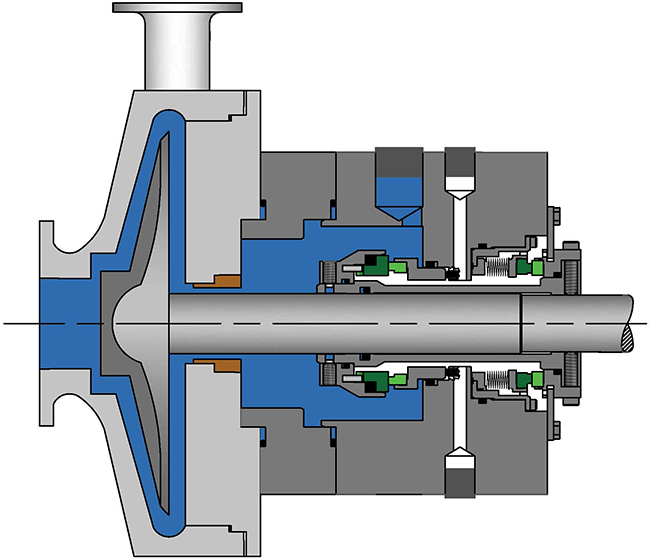

API Plan 61

Tapped and plugged atmospheric-side connections for the purchaser’s use.

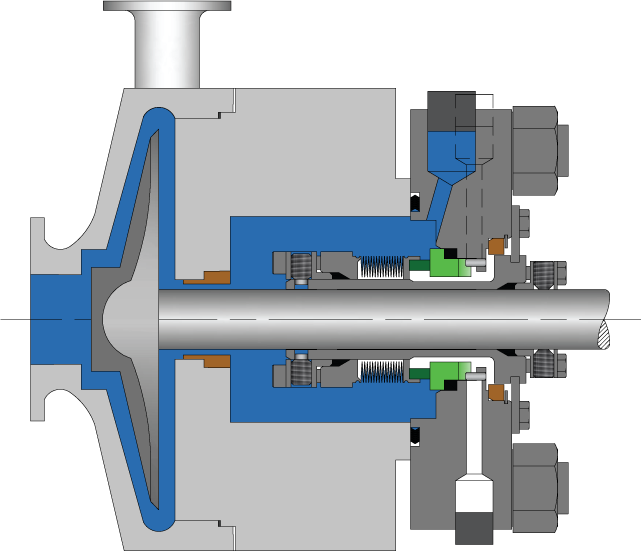

API Plan 62

Quench stream is brought from an external source to the atmospheric side of the seal.

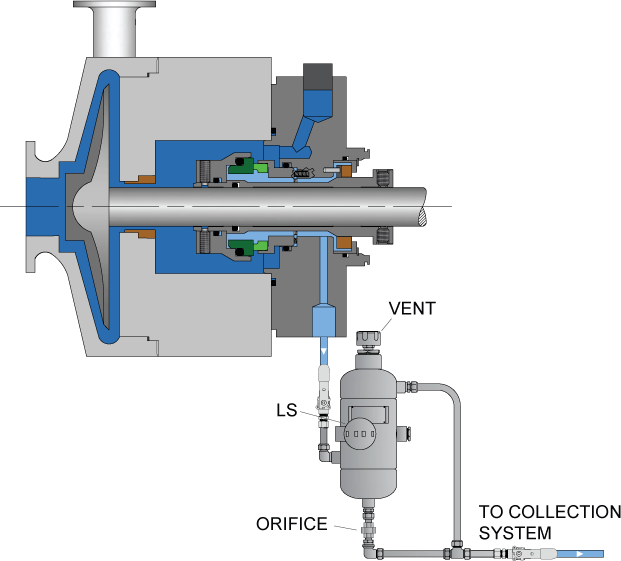

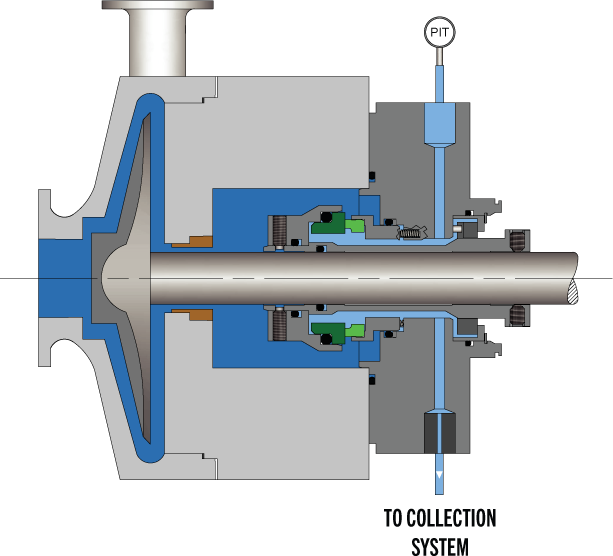

API Plan 65A

Atmospheric leakage collection and detection system for condensing leakage. Seal failure is detected by an excessive flow rate into the leakage collection system.

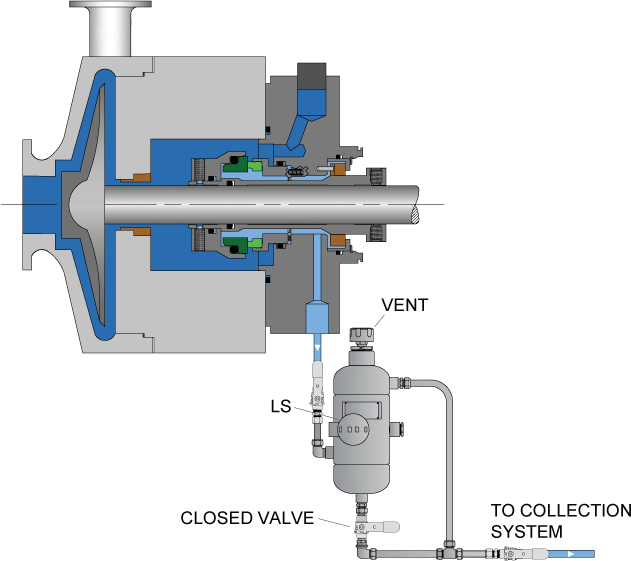

API Plan 65B

Atmospheric leakage collection and detection system for condensing leakage. Seal failure is detected by cumulative leakage into the leakage collection system.

API Plan 66A

Throttle bushings in the seal gland minimize the leakage leaving the seal gland and allows for detection of a seal failure.

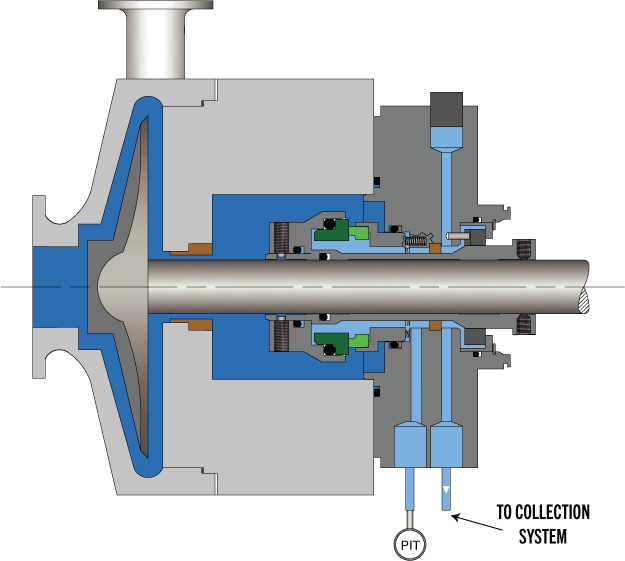

API Plan 66B

An orifice plug in the drain port minimizes the seal leakage leaving the seal gland and allows for detection of a seal failure.

API Plan 71

Tapped connections for the purchaser’s use in the future for buffer gas applications.