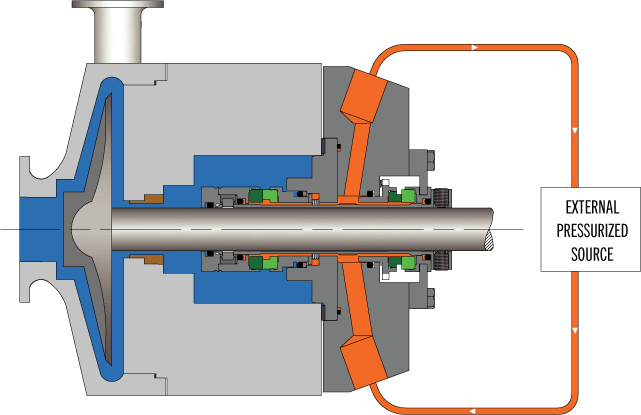

Pressurized external barrier liquid system supplying clean fluid to the inboard and outboard seal faces.

Description

Plan 54 involves the circulation of clean pressurized barrier fluid sourced from an external system. It is used in Arrangement 3 seals where barrier liquid pressures should remain at 20 psi or higher.

Application Notes

- Used with Arrangement 3 seals.

- Cool, clean product from an external source is supplied to the seal as a barrier liquid.

- Barrier liquid is maintained at a pressure greater than the seal chamber pressure.

- Barrier liquid pressure should always exceed the maximum seal chamber pressure by at least 20 psi [1.4 bar].

- Barrier liquid is circulated by an external pump.

- Process fluid never leaks to the atmosphere unless system pressure is lost.

- Superior management of seal generated heat due to higher flow rates than that of Plans 53A, 53B, and 53C.

- Provides barrier liquid cooling and circulation even if the process pump is not active.

- Sensors and flowmeters may be added within the external system to readily identify seal failure based on support system conditions.

- Barrier liquid must be compatible with the process liquid because it will leak into the product.

- If used on multiple seal installations, failure of one installation can affect all of the other installations unless proper precautions are taken to isolate the failed seal.

Pros:

- Provision of pressurized flow to multiple seals within one system

- No risk of process fluid leakage at proper system pressures

- Barrier fluids provide superior cooling

Cons:

- Barrier fluid and process fluids must be compatible due to the possibility of mixing

- Complex system with higher maintenance