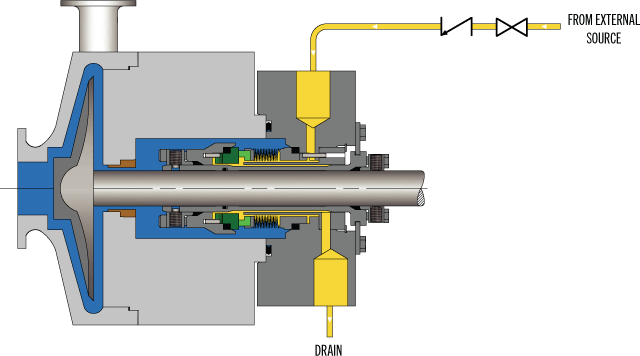

Quench stream is brought from an external source to the atmospheric side of the seal.

Description

This plan can be used to enhance the environment on the exposed side of single seals by quenching using steam.

Application Notes

- Quench is used to prevent unwanted material buildup on the atmospheric side of the seal faces.

- Must be used with a close clearance bushing or containment device in the seal gland to concentrate the quench to the desired target area.

- Quench pressure should be maintained between 2 to 7 psi [0.14 to 0.48 bar] to ensure purging of atmospheric gases.

- Often used with steam to avoid coking or crystallization in hot hydrocarbon services. Often used with nitrogen to avoid icing in cryogenic applications.

- Low-cost alternative to double seals to improve conditions on low-pressure side of process seal.

- Bushing contains the quench in the seal gland and also provides protection for personnel if a high temperature quench is being used.

- Proper controls must be in place to ensure steam does not condense and then boil, which could cause seal damage on hot processes.

Pros:

- Provides a low-cost substitute for tandem seals

- Quenching prevents coking and offers some degree of cooling

- Effective in both vertical and horizontal pumps

Cons:

- Leakage will lead to loss of pumped fluid to the exterior