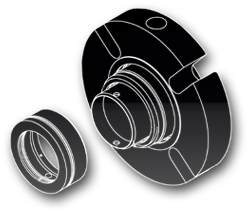

The U.S. Patent Office has granted the Flexaseal patent number US 7,979,986. for a “method of securing a cartridge mechanical face seal to a sleeve.”

The innovative system relocates the drive system outside of the product, isolating it from the wear of tough abrasives.

The Plunger Lock uses a thinner cross-section sleeve with more clearance between the seal OD and the seal chamber bore. The resulting design allows for more liquid around the seal, which effectively provides better face cooling.

The main difference between this spring-loaded plunger design and competing products is that it works in a relatively small area with a very low profile. This design style is unique in the seal industry.

The key advantages are:

- Simple Design

- Low Profile Design – the total height is very small

- Ease of Assembly – the rotor simply slides over the sleeve and locks into place

- Eliminates Face Distortion caused from tightening of set screws in similar designs

- Bi-directional – CW or CCW does not matter.

A Team Effort

Kim Simmons, inventor of the Plunger Lock idea, would like to recognize Kevin Davis along with the entire Flexaseal Engineering team that have assisted in developing this unique, ground breaking “Plunger Lock” design. The dedicated hard work of the Engineering group, along with the rest of the Flexaseal team, all helped to bring this new innovative design to the seal market.