Flexaseal dry gas seals bring non‑contacting, gas‑lubricated performance to process pumps and high‑energy rotating equipment where reliability, cleanliness, and emissions control are critical. By sustaining a precision gas film between the faces, our seals run cool, minimize wear, and eliminate liquid support systems—helping you reduce fugitive emissions, extend MTBR, and lower total cost of ownership. From new builds to retrofits, Flexaseal engineering supports you end‑to‑end with application review, seal selection, and startup best practices.

What Is a Dry Gas Mechanical Seal?

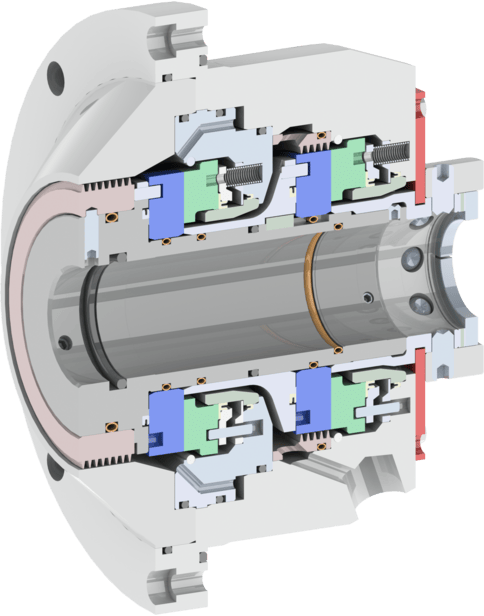

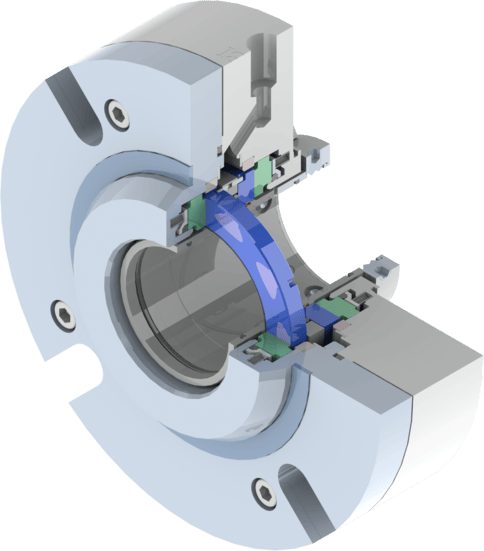

A dry gas seal is a non‑contacting, dry‑running mechanical face seal that uses engineered laser-etched grooves to generate a thin, pressurized gas film between a rotating face and a stationary face. This contact‑free operation:

- Reduces friction and heat, limiting face wear and distortion

- Removes the need for liquid lubrication, avoiding contamination of the process

- Enables very low leakage, supporting environmental performance goals

Typical buffer or barrier media include nitrogen or clean process gas, supplied and managed via standard seal support systems.

Where Dry Gas Seals Make a Difference

- Contact-free operation reduces friction and face wear for longer service life

- Light/volatile and low‑lubricity fluids where liquid‑film seals struggle

- Clean or filtered product services requiring ultra‑low leakage and no lubricant carryover

- Lower emissions and environmental impact through near-zeroleakage

- Energy-efficient design minimizes power consumption and operating costs

- Retrofits replacing complex double liquid seals and barrier oil systems

- Reduced maintenance and downtime for improved overall equipment effectiveness (OEE)

Dry Gas Mechanical Seals

Retrofitting With Dry Gas Seals

Upgrading older compressors with modern dry gas seal technology can significantly improve reliability, reduce emissions, and extend equipment lifespan. Unlike traditional oil-lubricated seals, dry gas seals require no oil systems, simplifying maintenance and reducing potential leakage pathways.

Flexaseal provides custom retrofit solutions that integrate seamlessly into your existing compressor housings. Our engineers evaluate your current system and recommend the most effective retrofit design to deliver measurable gains in uptime, efficiency, and environmental performance.

Seal Gas Support Systems

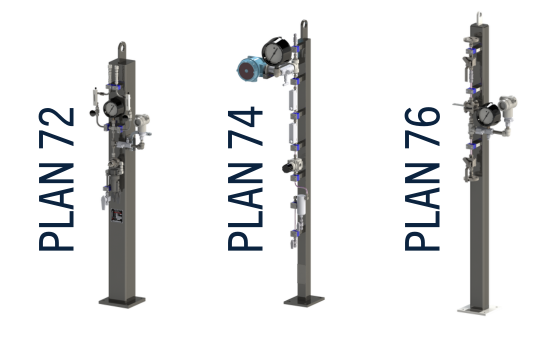

For optimal operation, dry gas seals depend on properly conditioned and monitored seal support gas supply. Flexaseal offers complete seal gas support systems that regulate gas flow, pressure, and cleanliness to ensure stable seal performance.

Our integrated systems include:

- Gas conditioning and filtration modules

- Flow and pressure control assemblies

- Seal gas recovery and vent management units

- Monitoring and diagnostics solutions for predictive maintenance

Typical support plans consist of API 682 72, 74, and 76.

Frequently Asked Questions

No. While historically associated with compressors, non‑contacting gas‑lubricated seals are highly effective in process pumps and high‑energy rotating equipment, especially with light hydrocarbons, inert gases, and applications targeting low leakage and clean operation.

Common choices include nitrogen or clean process gas, supplied through API Plan 72 (unpressurized buffer) or 74 (pressurized barrier) and supported by appropriate filtration and monitoring. The objective is a stable, clean gas film that keeps faces separated.

Dry gas seals eliminate liquid buffer/barrier support systems, reducing complexity and potential process contamination. They run cooler with very little friction and can achieve very low leakage when properly supported by a well-designed gas panel and controls.

Yes. We evaluate existing seal chamber geometry, axial space, shaft dynamics, and system utilities to recommend a fit‑for‑purpose retrofit—including gas panel specification, filtration, and vent management (e.g., API Plan 76).

Why Choose Flexaseal

As a U.S.-based manufacturer, Flexaseal designs and builds precision-engineered mechanical seals for industries that demand reliability and performance. Every dry gas seal is backed by expert technical support and global service capabilities. We work directly with operators and OEMs to provide optimized sealing solutions tailored to each application.

When performance, safety, and environmental responsibility matter—Flexaseal delivers.