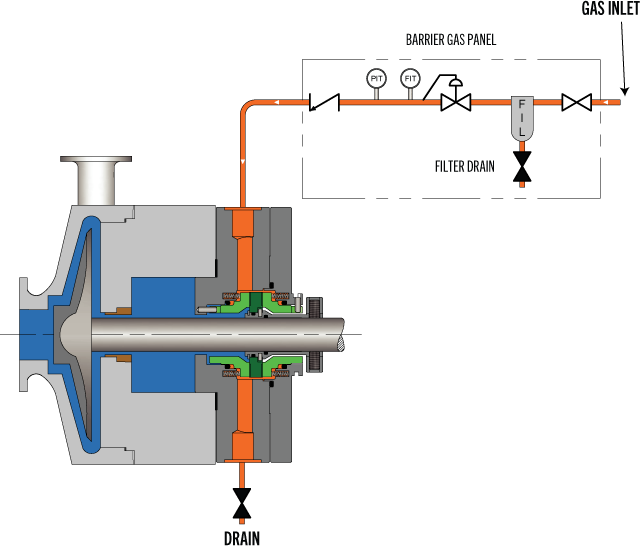

Externally supplied barrier gas maintained at a pressure greater than the seal chamber pressure.

Description

Plan 74 uses a barrier gas such as nitrogen in a dual seal system regulated by a control panel which allows the removal of moisture, gas filtration and barrier pressure regulation.

Application Notes

- Used in Arrangement 3 dual pressurized seals, where the barrier medium is a gas.

- Most common barrier gas is nitrogen. Ensure a reliable supply and avoid the use of bottles if possible.

- Barrier gas must be pressurized prior to filling the pump and this pressure must be maintained at all times, including during standby.

- Used with non-contacting and contacting mechanical seal solutions.

- Typically used in applications that may contain toxic or hazardous materials whose leakage cannot be tolerated.

- Barrier-fluid leakage to atmosphere is an inert gas (e.g. N2). Drainage and cleanup is not an issue as with dual liquid systems.

- Inert barrier gas can be easily separated from the process stream.

- Not recommended for services where sticky or polymerizing agents will be in direct contact with the seal faces; similarly, avoid applications that may lead to solids buildup.

Pros:

- Low installation and maintenance costs

- Better safety profile as buffer gas leakage is inert

Cons:

- Discouraged in applications using polymerizing agents