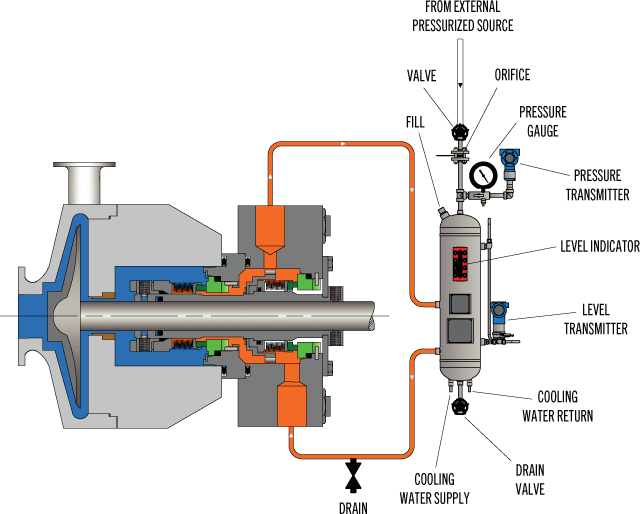

Pressurized external barrier liquid reservoir supplying clean fluid to the inboard and outboard seal faces.

Description

This plan is used in Arrangement 3 seals and requires the use of a pressurized barrier fluid seal reservoir and forced circulation via a pumping ring.

Application Notes

- Used with Arrangement 3 seals.

- Typically chosen for dirty, abrasive, or polymerizing products not compatible with a Plan 32.

- Barrier liquid is maintained at a pressure greater than the seal chamber pressure. It is recommended that the barrier liquid pressure always exceeds the maximum seal chamber pressure by at least 20 psi [1.4 bar].

- Circulation of barrier liquid to and from the reservoir is dependent on thermal siphoning and/or an internal circulating device (pumping ring) inside the seal.

- Used when no process leakage to the atmosphere can be tolerated.

- Process fluid never leaks to the atmosphere unless reservoir pressure is lost.

- Cooling system is typically built into the reservoir.

- Barrier liquid must be compatible with the process liquid because it will leak into the product.

- Best piping practices must be followed to avoid vapor entrapment and stalled flow in the tubing.

Pros:

- No process fluid leaks

- Integral cooling system

Cons:

- Barrier fluids might undergo gas entrapment

- Requires strict adherence to best piping practices

- Barrier fluid levels must be maintained

- Barrier fluid and process fluids must be compatible due to the possibility of mixing