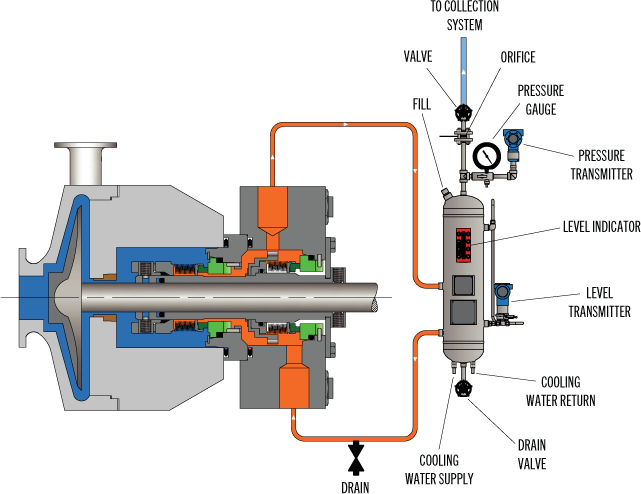

External buffer liquid reservoir supplying clean fluid to the outboard seal faces.

Description

This plan is used in Arrangement 2 seals and requires the use of an unpressurized external pump seal pot and forced circulation via a pumping ring.

Application Notes

- Used with Arrangement 2 seals.

- Buffer system pressure is typically maintained close to atmospheric pressure.

- Used in applications where product contamination from a barrier fluid is unacceptable.

- Circulation of buffer liquid to and from the reservoir is dependent on thermal siphoning and/or an internal circulating device (pumping ring) inside the seal.

- Used with clean, non-polymerizing, pure products that have a vapor pressure higher than the buffer system pressure.

- Provides redundancy in the event of a seal failure.

- Leakage of higher vapor pressure liquids into the buffer system will flash in the seal reservoir and the vapor can escape into the collection system.

- Near zero process emissions.

- Cooling system is typically built into the reservoir.

- Buffer liquid must be compatible with the process liquid.

- Best piping practices must be followed to avoid vapor entrapment and stalled flow in the tubing.

Pros:

- No process fluid contamination

- Near-zero process emissions

- Integral cooling system

Cons:

- Buffer fluid is easily contaminated over time

- Requires strict adherence to best piping practices

- Seal pot maintenance high with process fluids that solidify