DIAMOND-COATING SEAL FACE TECHNOLOGY

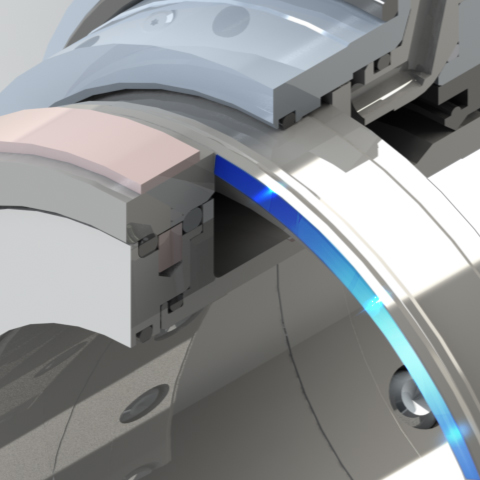

FlexICE™ Diamond Face Technology for Mechanical Seals

Solve chronic seal failures while cutting cooling water and power use

FlexICE™ is Flexaseal’s advanced diamond-bond coating engineered to dramatically extend the life and performance of your most challenging mechanical seal applications. Applied to silicon or tungsten carbide seal faces, FlexICE™ delivers exceptional hardness, ultra-low friction, and superior thermal conductivity, allowing seals to handle dry running, frequent stop/starts, and low-lubricity fluids where traditional materials fail. The result: higher reliability, longer MTBR, and reduced total cost of ownership across some of your toughest applications.

WHY USE FLEXICE™

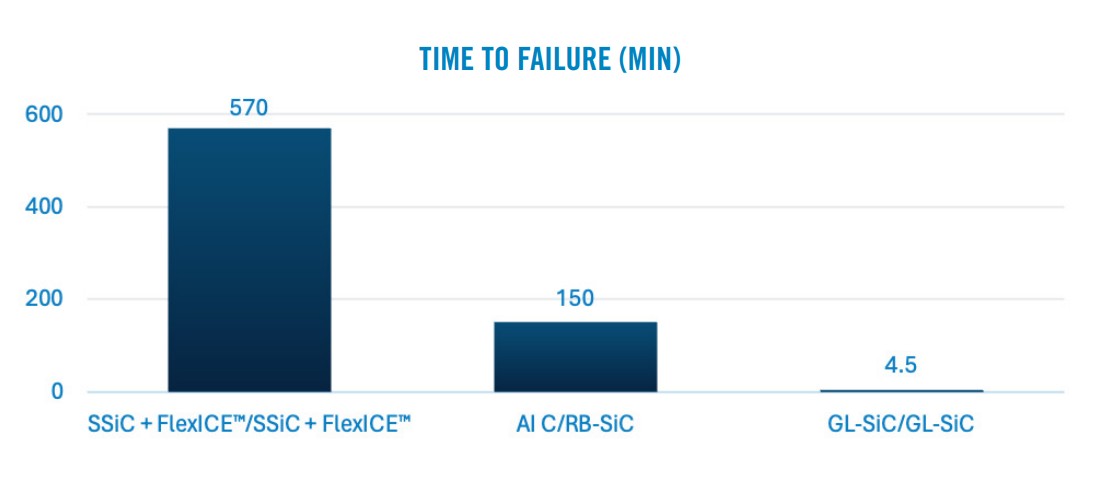

- Intermittent dry running and frequent stop/starts are tolerated, when otherwise temperatures would spike, causing elastomer failures, face blistering and leaks.

- Low-lubricity fluids like hot water, condensate, and light hydrocarbons can be sealed because FlexICE™ coated faces are less reliant on a stable fluid film for support.

- Ultra-high face hardness prevents damage from solids and abrasives.

- Lower friction and cooling water demands reduce costs of auxiliary support.

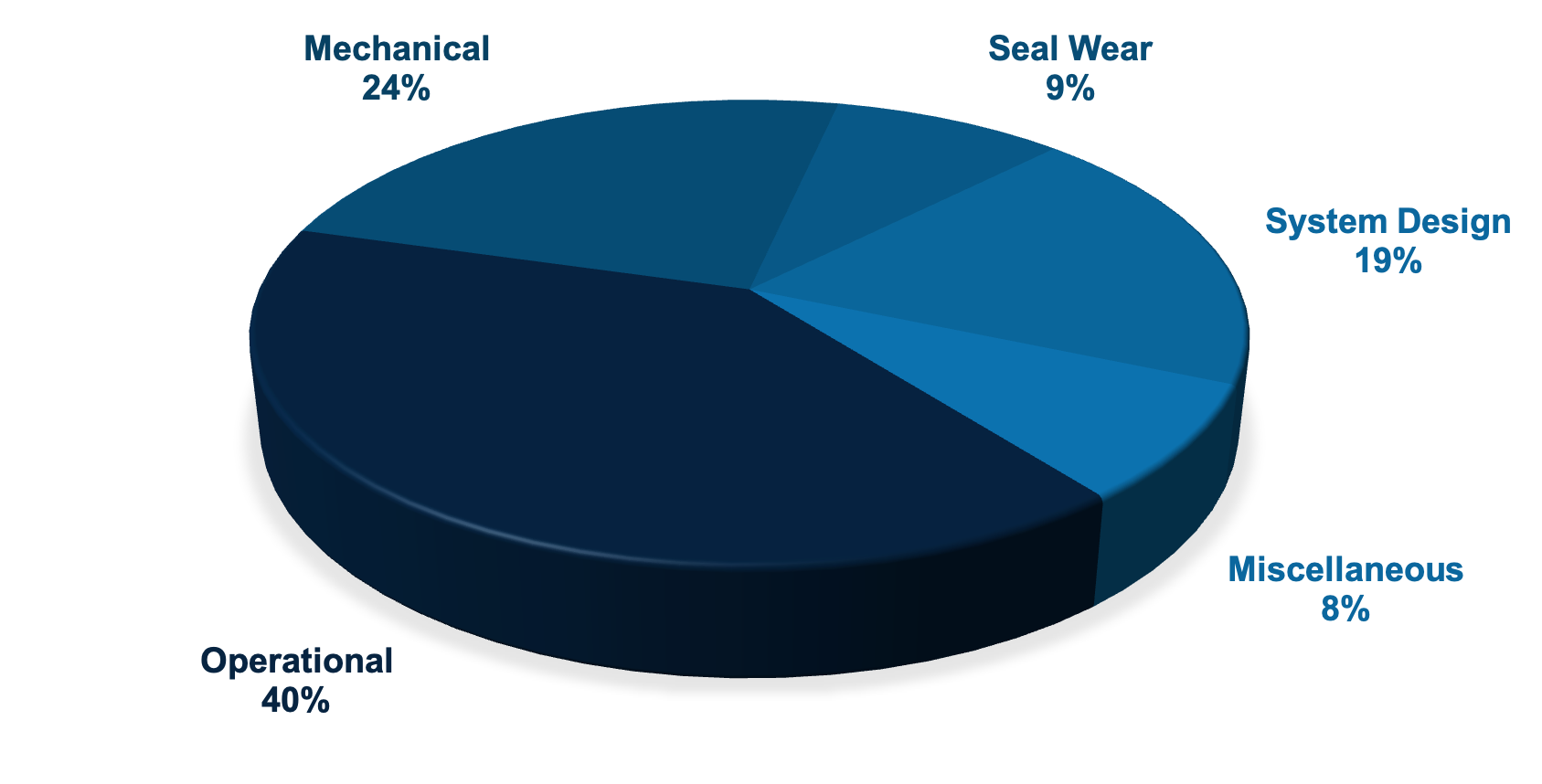

Dry Run Test Data

Specifications

Coating Parameters

| Coefficient of Friction | 0.025 (nominal) |

| Coating Hardness | 3,500–4,000 Hv |

| Max Temperature | 932° F (500° C) |

| Coating Thickness (typ) | 6–15 µm (240–590 µ-in) |

*Max temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal if in doubt.

Downloads

For more information on Diamond Face Technology for Mechanical Seals

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

APPLY FLEXICE™ FOR MANY OPERATIONAL CHALLENGES

FlexICE™ technology on mechanical seal faces directly addresses the operational weaknesses that cause many seal failures. By creating an ultra-hard, low-friction, thermally conductive barrier, FlexICE™ faces:

- Tolerate intermittent dry-running during start-up, shutdown, or upset.

- Perform reliably in low-lubricity fluids such as hot condensate, light hydrocarbons, and fluids with entrained gas.

- Resist abrasive wear from slurries, fibers, or particulates, maintaining flatness and seal integrity.

- Run cooler and more efficiently, reducing auxiliary cooling demand and energy losses.

The result is often a significant increase in Mean Time Between Repair (MTBR), particularly in bad-actor applications where conventional seals routinely fail.