Features

Product Line Features

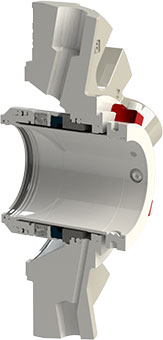

- Simple cartridge seal installation.

- Sleeve is isolated from process fluid.

- 3/8″ NPT flush connection allows for cooling and venting of seal.

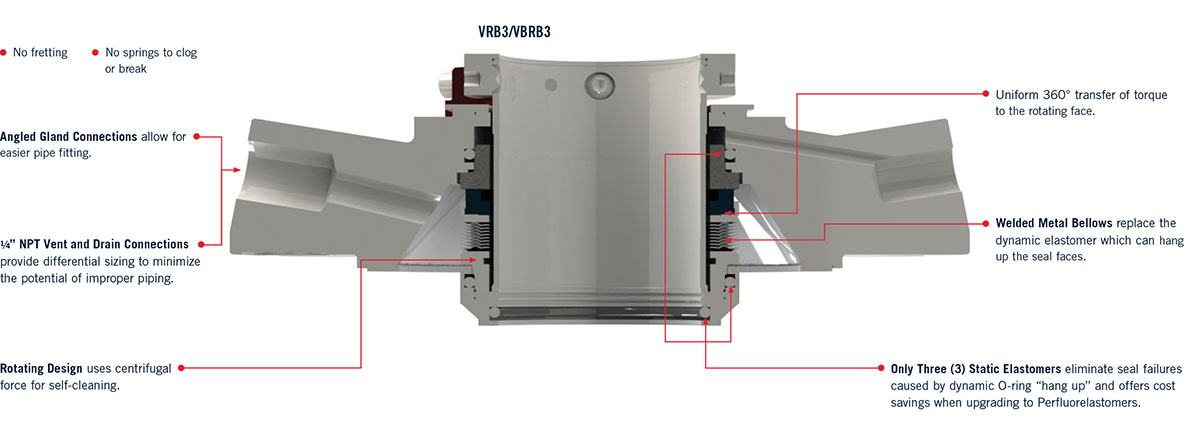

- 1/4″ NPT vent and drain connections provide differential sizing to minimize the potential of improper piping.

- Non-sparking throttle bushing is positively retained to avoid pressure blow out, minimizing leakage in the event of seal failure.

- Vantage seal glands include flush, vent, and drain connections and a close-clearance, non-sparking throttle bushing to direct any leakage to the drain connection.

- Flush, vent, and drain connections available to be piped at multiple locations.

- Angled gland connections allow for easier pipe fitting.

- Setting clips provide positive axial and radial settingof the Vantage cartridge seal to ensure proper seal installation. The Vantage setting clips are easy to access for simple removal.

- Convertible gland design to accept over four (4) design configurations.

VRB3/VBRB3 Features

- Rotating design uses centrifugal force for self-cleaning

- Uniform 360° transfer of torque to the rotating face

- Welded metal bellows replace the dynamic elastomer which can hang up the seal faces

- No springs to clog or break

- No fretting

- Only three (3) static elastomers – eliminate seal failures caused by dynamic O-ring “hang up” and offers cost savings when upgrading to Perfluorelastomers.

Specifications

Materials of Construction

| Rotating Seal Face: | Carbon, Tungsten Carbide, Sintered Silicon Carbide |

| Stationary Seal face: | Sintered Silicon Carbide |

| Bellows: | Hastelloy® C276 |

| Metallurgy: | 316 SS |

| Elastomers: | Viton®, Ethylene Propylene, Aflas®, Buna, Neoprene, Perfluorelastomer |

| Gland Gasket: | Glass-filled Teflon™ |

| Throttle Bushing: | Glass-filled Teflon™ |

Operating Parameters

| Temperature: | 400°F (200°C) |

| Pressure: | 300 PSI (20 Bar) |

| Speed: | 6000 FPM |

Note: Maximum temperature/speed/pressure/runout indicates operating extremes independently and does not imply the seal will function at these extremes at the same time.

Registered Trademarks:

Viton® – Dupont Performance Elastomers; Aflas® – Asahi Glass Co.;

Teflon® – E.I.Dupont de Nemours and Co; Hastelloy® – Haynes International, Inc.

Downloads

For more information on the ANSI VRB3/VBRB3

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.