Choosing the correct seal support system for your application – whether liquid or gas, extreme temperatures, abrasives, or other volatile conditions – is crucial for system reliability. Support system designs can include barrier or buffer fluid reservoirs, filtration systems, heat exchangers, and/or gas panels. Flexaseal Engineered Seals and Systems has the expertise to guide you in selecting the best option for your sealing challenge.

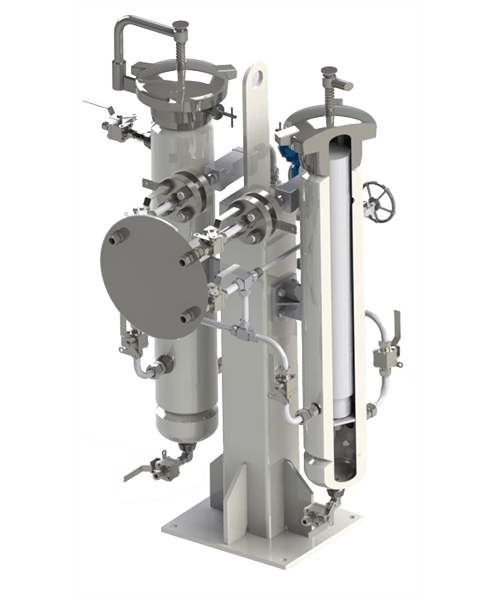

Lube Oil Systems

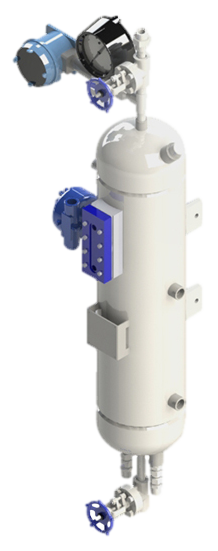

Barrier Fluid Reservoirs

Primary Seal Monitoring Systems

Filtration Systems

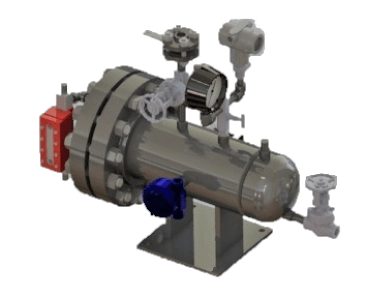

Heat Exchangers

Parts

ViseSeal ORV

Dual Seal Water Flush Control Device

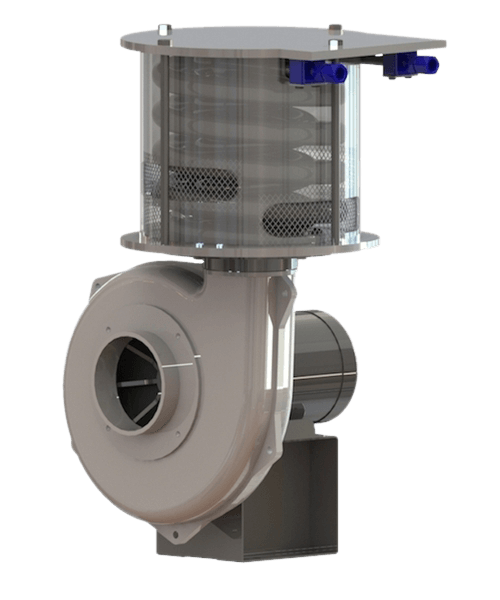

Cyclone Separator

Quick Contact

For general inquiries, sales or quotes.