Mechanical seals are critical components that prevent fluid leakage between a rotating shaft and stationary housing in pumps, compressors, mixers, and agitators. By creating a secure seal at the shaft interface, they ensure equipment reliability, efficiency, and compliance with environmental and safety regulations.

Flexaseal designs and manufactures high-performance mechanical seals in the U.S., engineered for the most demanding applications. From chemical processing and oil & gas to water treatment, power generation, and pharmaceuticals, our seals deliver exceptional performance, longer service life, and reduced downtime.

Mechanical Seals Products

When selecting a mechanical seal, it’s important to match the design to your application, installation, and operating conditions. Flexaseal offers cartridge, split, double, metal bellows, component, and multi-lip seals—engineered with advanced materials to withstand high pressures, extreme temperatures, abrasive fluids, and demanding operating speeds. Our mechanical seal products deliver reliable performance for pumps, compressors, mixers, and other rotating equipment.

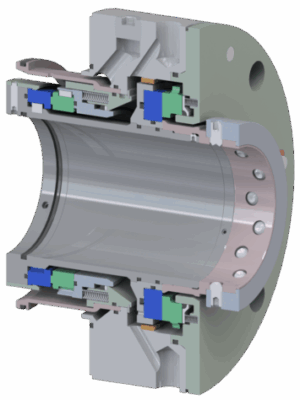

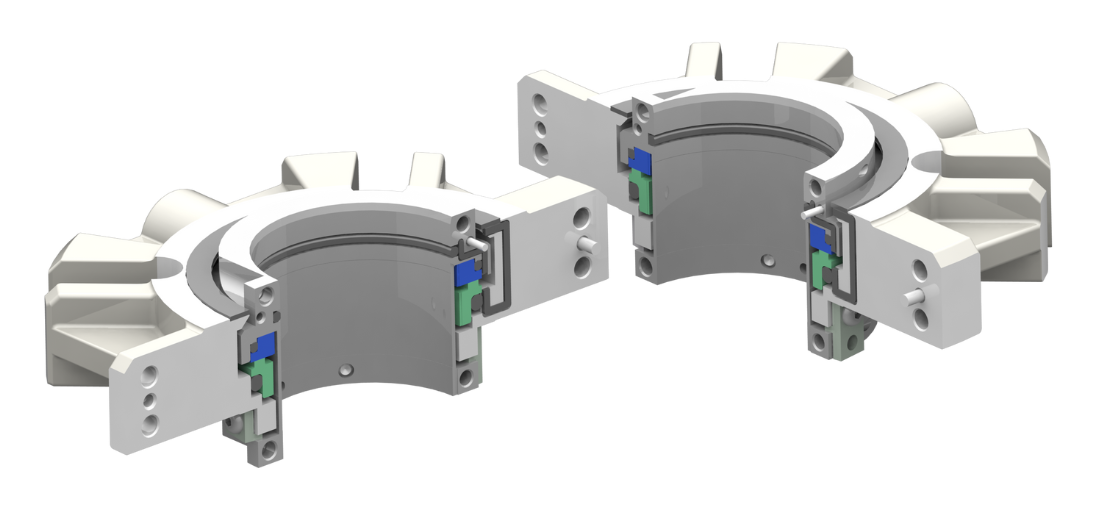

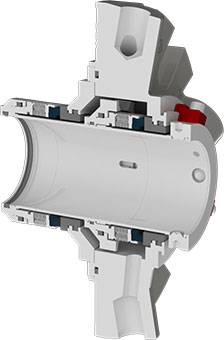

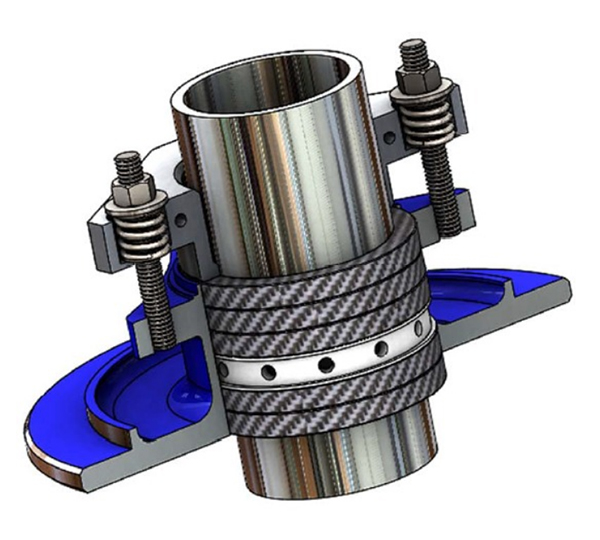

Split Seals

Simplified installation without equipment disassembly.

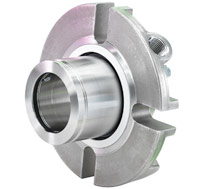

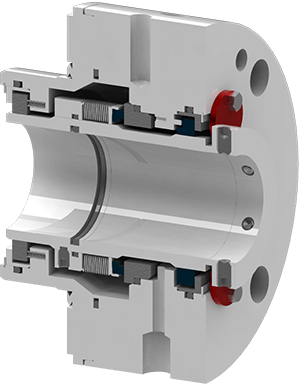

Cartridge Seals

Easy installation, reduced maintenance for pumps, mixers, and compressors.

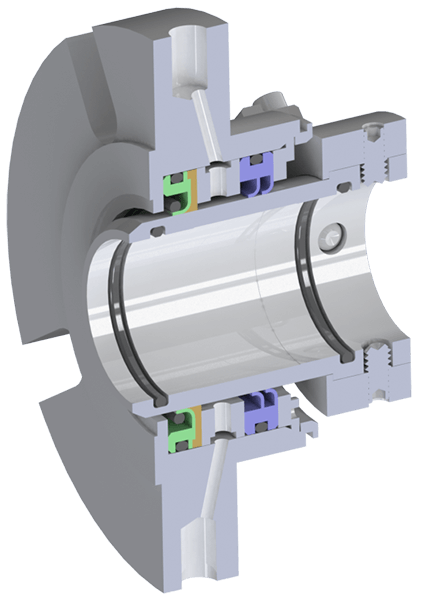

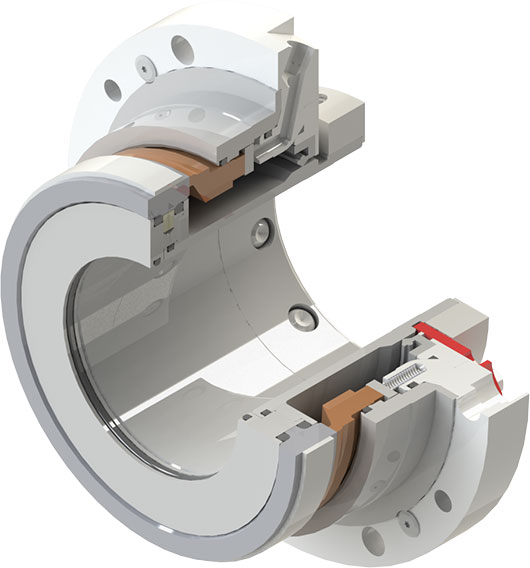

Dual Cartridge Seals

Enhanced safety, ideal for hazardous fluids. Oil & Gas, Chemical Processing.

Multi-Lip Cartridge Seal

Protection against contaminants for slurry, wastewater, and abrasive media.

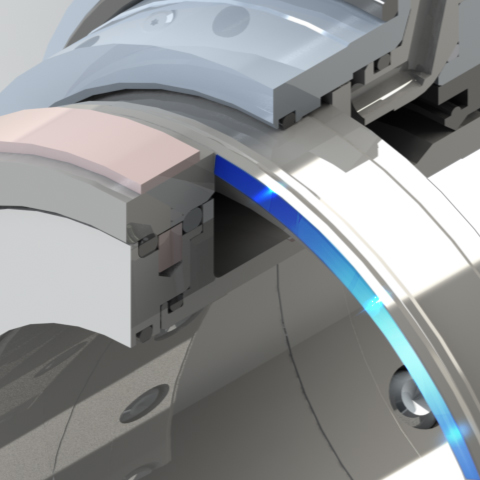

Edge Welded Metal Bellows

Handles high temperature/pressure, corrosion resistance.

Component Seals

Versatile and economical for general industry pumps, mixers.

Product Applications

Flexaseal’s mechanical seals are trusted across industries where equipment reliability is critical. From oil and gas refineries and power generation plants to pulp and paper mills, pharmaceutical production, and water and wastewater treatment facilities, our seals are engineered to perform in demanding environments. Designed for easier installation, reduced maintenance, and longer service life, each seal is backed by decades of engineering expertise and U.S.-based manufacturing. Whether you need API 682–compliant seals for petrochemical operations, slurry seals for mining and mineral processing, or sanitary seals for food and pharmaceutical mixers, Flexaseal delivers application-specific sealing solutions tailored to your operating conditions.

API Seals

API 682 seals for oil, gas, and petrochemical use.

ANSI Seals

Durable seals designed for ANSI pump applications.

Slurry Seals

Heavy-duty seals for abrasive slurry and mining.

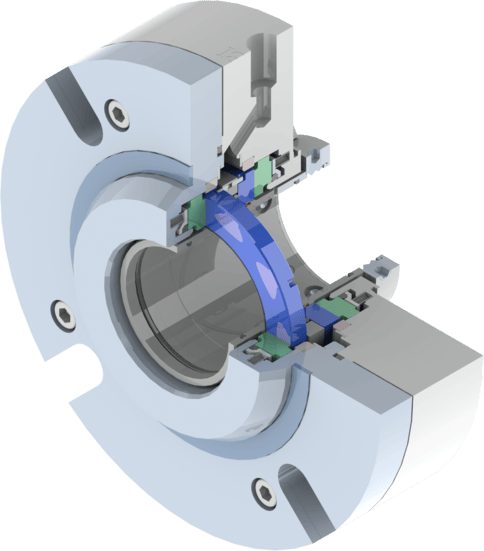

Gas Seals

Dry Gas Seals for Industrial and High Energy Pumps and Compressors.

Mixer/Agitator Seals

Sanitary seals for food, chemical, and pharma use.

Compressor Seals

Reliable seals for pumps, mixers, and compressors.

Additional Sealing Solutions

Flexaseal offers more than just mechanical seals. Our full product line includes OEM replacement seals, braided packing, and gland packing — each engineered for reliable performance, easier maintenance, and long-lasting equipment protection across a wide range of industrial applications.

OEM Replacement Seals

Reliable OEM seal replacements with fast delivery.

Braided Packing

Durable braided packing for pumps, valves, and mixers.

Gland Packing

Cost-effective gland packing for dependable sealing.

Diamond Face Technology for Mechanical Seals

Solve chronic seal failures while cutting cooling water and power use.

Seal Support Systems for Pumps

Flexaseal offers a complete range of engineered seal support systems, including pressure reservoirs, gas seal control panels, heat exchangers, and abrasive separators. These components can be configured to create an optimized system for any application, delivering the ideal operating environment to maximize mechanical seal performance, reliability, and service life.

Why Choose Flexaseal?

Flexaseal is more than a seal manufacturer — we are an engineering partner dedicated to helping our customers achieve safer, more reliable, and more efficient operations. With U.S.-based manufacturing, decades of application expertise, and proven performance in mission-critical environments, Flexaseal delivers sealing solutions tailored to your exact operating conditions.

- U.S.-Based Manufacturing – Strict quality control and faster lead times.

- Four Repair Locations – Quick, reliable seal repair and refurbishment.

- Reliability Solutions – Leak-free, long-lasting performance for rotating equipment.

- Global Reach – Trusted sealing solutions in over 30 countries worldwide.