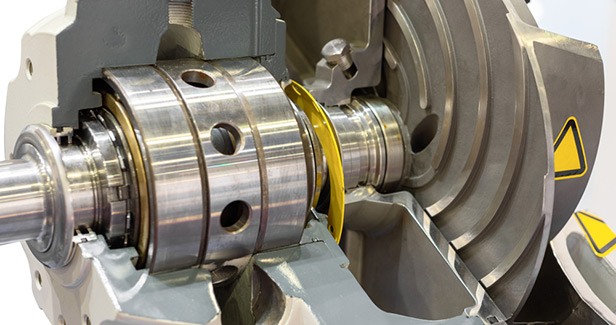

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by creating a barrier between the rotating shaft and the pump casing as the shaft rotates, preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

Depending on the pump type and the process variables, there are various mechanical seal types to choose from. Each seal variant has its unique design and characteristics, which make it suitable for a specific application. Flexaseal has years of experience with industrial mechanical seals and support systems, making us an authority in this area.

This article highlights the benefits and drawbacks of the different types of mechanical seals used in centrifugal pumps.

Key Takeaways

6 Types of Mechanical Seals for Centrifugal Pumps

Mechanical seal types vary in design, arrangement, and how they control the hydraulic forces acting at their faces. The most common seal types include the following:

1. Balanced Seals

Balanced mechanical seal arrangements refer to a system where the forces acting at the seal faces are balanced. As a result of the lower face loading, there is more even lubrication of the seal faces and longer seal life. Learn about our mechanical seal lubrication systems today.

Balanced mechanical seals are particularly suited to higher operating pressures, typically above 200 PSIG. They are also a good choice when handling liquids with low lubricity and higher volatility.

2. Unbalanced Seals

Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result, they can exhibit much lower mean time between failure. Unbalanced seals are not recommended for high-pressure or most hydrocarbon applications.

3. Pusher Seals

Pusher seals utilize one or multiple springs to maintain seal closing forces. The springs can be in the rotating part (rotary part) or the stationary part of the mechanical seal, depending on the specific design requirements.

Pusher-type seals can provide sealing at very high pressures but have a drawback due to the elastomer (typically an o-ring) under the primary seal face that can be subjected to wear as the face moves along the shaft/sleeve during operation.

4. Non-pusher Seals

Non-pusher seals utilize a metal or elastomeric bellows to maintain seal closing forces. These seals are ideally suited to dirty and high-temperature applications. Bellows seals are limited to medium/lower pressure applications.

Both pusher and non-pusher designs are available in balanced and unbalanced configurations.

5. Conventional Mechanical Seals

Conventional seals are typically lower cost and often installed on general service equipment. These seals are installed directly into the pump’s stuffing box as individual components, requiring higher operator skill to service.

6. Cartridge Type Seals

Cartridge-type mechanical seals incorporate all of the seal elements into a single assembly that is self contained, pre-loaded and ready to install without any measurements required. This dramatically reduces the potential for assembly error and the time required for seal replacements. Learn more about the difference between cartridge and non-cartridge mechanical seals here.

Why Can Centrifugal Pumps Use So Many Types of Mechanical Seals?

Centrifugal pumps create unique sealing challenges that drive the need for diverse mechanical seal designs. The centrifugal action generates varying pressures at different points in the pump casing, creating pressure differentials that can range from near-vacuum conditions at the impeller eye to high discharge pressures at the volute.

These pumps also experience shaft deflection under hydraulic loads, thermal growth during startup and shutdown cycles, and vibration from impeller imbalance—all of which affect seal face alignment and contact pressure.

Additionally, centrifugal pumps handle everything from clean condensate at low pressures to high-pressure hydrocarbon streams with entrained solids, requiring seal designs that can accommodate dramatically different sealing environments within the same basic pump configuration.

Key Considerations When Choosing Different Types of Mechanical Seals for Pumps

When deciding on the type of seal system for a centrifugal pump, operators must choose according to their unique demanding applications. Failure to select the proper seal type can lead to loss of containment integrity, breakdowns and costly repairs. To avoid these undesirable results, all operators must consider the following factors before deciding.

Type of Fluid to Be Pumped

The fluid that you’re pumping is the single most important factor to consider when deciding on a seal type.

Factors such as cleanliness, lubricity and volatility will significantly affect the mechanical seal and seal support system design.

For example, abrasive fluids containing particles require hardened seal faces and robust designs, while corrosive chemicals demand specialized materials like special silicon carbide. Low-lubricity fluids such as water or light hydrocarbons may necessitate external lubrication systems to prevent premature seal face wear.

Pump Fluid Pressure

The amount of pressure exerted at a mechanical seal’s faces has a significant effect on its performance. If a pump is to be operated at low pressures, an unbalanced mechanical seal will be suitable. However, in conditions where higher pressures are anticipated, balanced seals will prove a more reliable solution.

For instance, cooling water systems typically operate at 50-150 PSIG and work well with unbalanced seals, while high-pressure boiler feed pumps operating at 500+ PSIG require balanced seal designs to handle the increased hydraulic forces.

Temperature Considerations

Balanced mechanical seals perform better than their unbalanced counterparts in conditions where the operating temperatures are higher than normal. Heat-sensitive components are better preserved in balanced mechanical seals compared to other seal types.

For example, hot oil transfer pumps operating at 300°F or steam condensate systems at 250°F+ benefit from balanced seal designs, as the reduced face loading generates less heat and prevents thermal distortion of elastomeric components.

Operator Safety Concerns

As it goes for all types of machinery, operator safety is the top priority. The use of double mechanical seals (two mechanical seals working in tandem) in centrifugal pumps provides additional protection as they have increased sealing capacity and are generally more reliable.

Let Flexaseal Extend the Lifetime of Your Mechanical Seals

Choosing the right mechanical seal type is just the beginning—proper installation, monitoring, and seal support systems are what transform a good seal selection into years of reliable operation. Flexaseal brings decades of real-world experience to help you navigate these critical decisions, from initial seal specification through ongoing performance optimization.

Whether you’re dealing with challenging process conditions, frequent seal failures, or simply want to maximize your pump reliability, our team has the expertise to deliver solutions that work.