Elevate Your Operations with Flexaseal’s Reliability Solutions

Engineered Excellence, Designed for You

We understand the heartbeat of your plant lies in the smooth operation of rotating equipment. Our Reliability Solutions are designed to keep your operations running efficiently, minimizing downtime and maximizing productivity. With our expertise, your plant’s reliability is in expert hands.

Reliability is the heartbeat of productivity. But every plant faces its challenges.

Misalignment, lubrication issues, and vibration are just a few problems that can lead to equipment failures, often impacting or indicated by mechanical seals – the critical components underpinning your operation’s reliability.

Asset Management

Seals and Pumps

Ensure the integrity and performance of your equipment with our top-tier mechanical seals and pump solutions.

System Assessments

Our comprehensive evaluations identify potential issues before they become costly problems.

Service and Repair Centers

From inventory management to repair analysis, we handle the details so you can focus on your core operations.

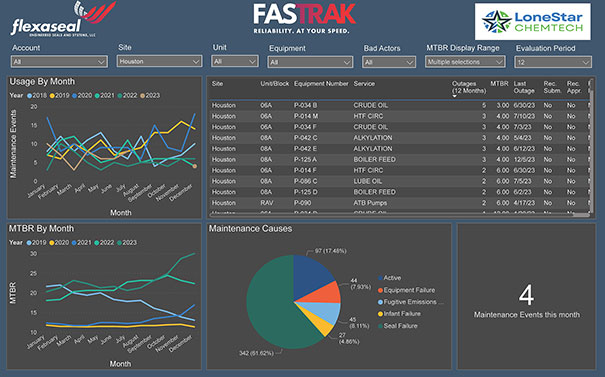

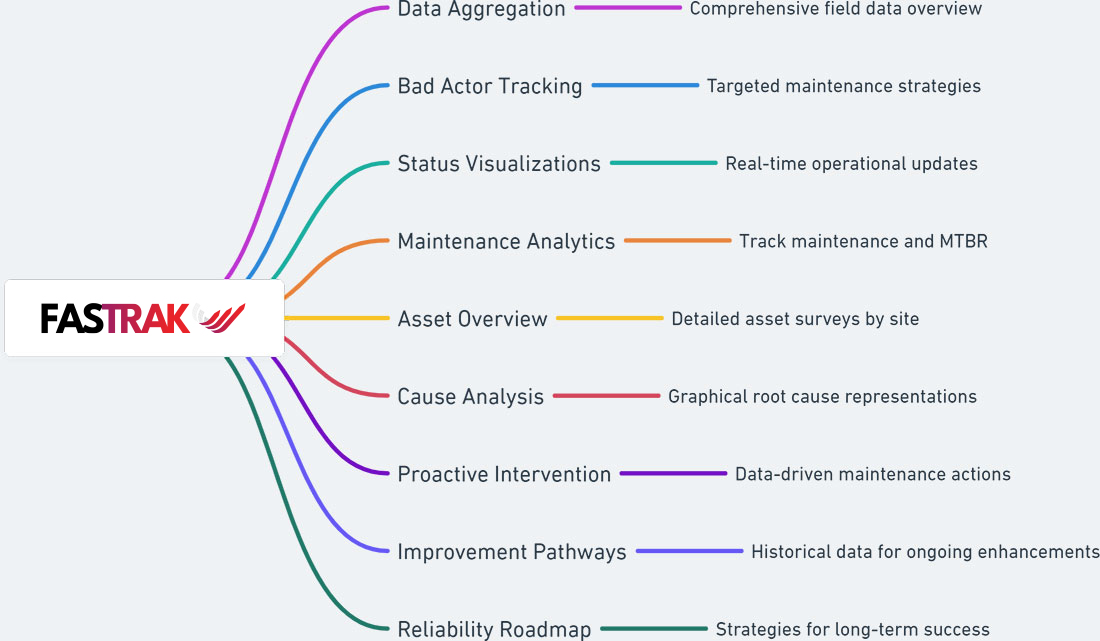

Your Data Visualization Powerhouse

Your Data Visualization Powerhouse

Unlock the full potential of your plant’s reliability with FASTRAK™, Flexaseal’s proprietary data visualization software. FASTRAK™ transforms complex data into clear, actionable insights, empowering you to make informed decisions for enhanced operational success. FASTRAK™ will elevate your asset management to the next level!

Advanced Predictive Services

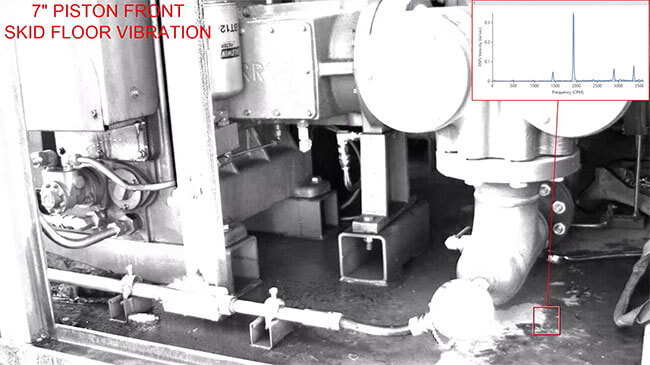

Vibration Monitoring

Stay ahead of wear and tear with our precise vibration tracking, predicting issues before they arise.

Motion Amplification Studies

Visualize the unseen with our motion amplification technology, pinpointing trouble areas and misalignments.

Thermography

Our thermal imaging detects hotspots and thermal anomalies, preventing thermal stress damage from chronic overheating.

Ultrasonic Bearing Analysis

Protect your bearings with ultrasonic technology, catching the early signs of issues and intervening before failure.

Laser Alignment

Precision alignment services reduce the risk of vibration and extend equipment life.

Oil Analysis

Keep your lubrication up to factory spec with our thorough oil analysis, preventing contamination and friction issues.

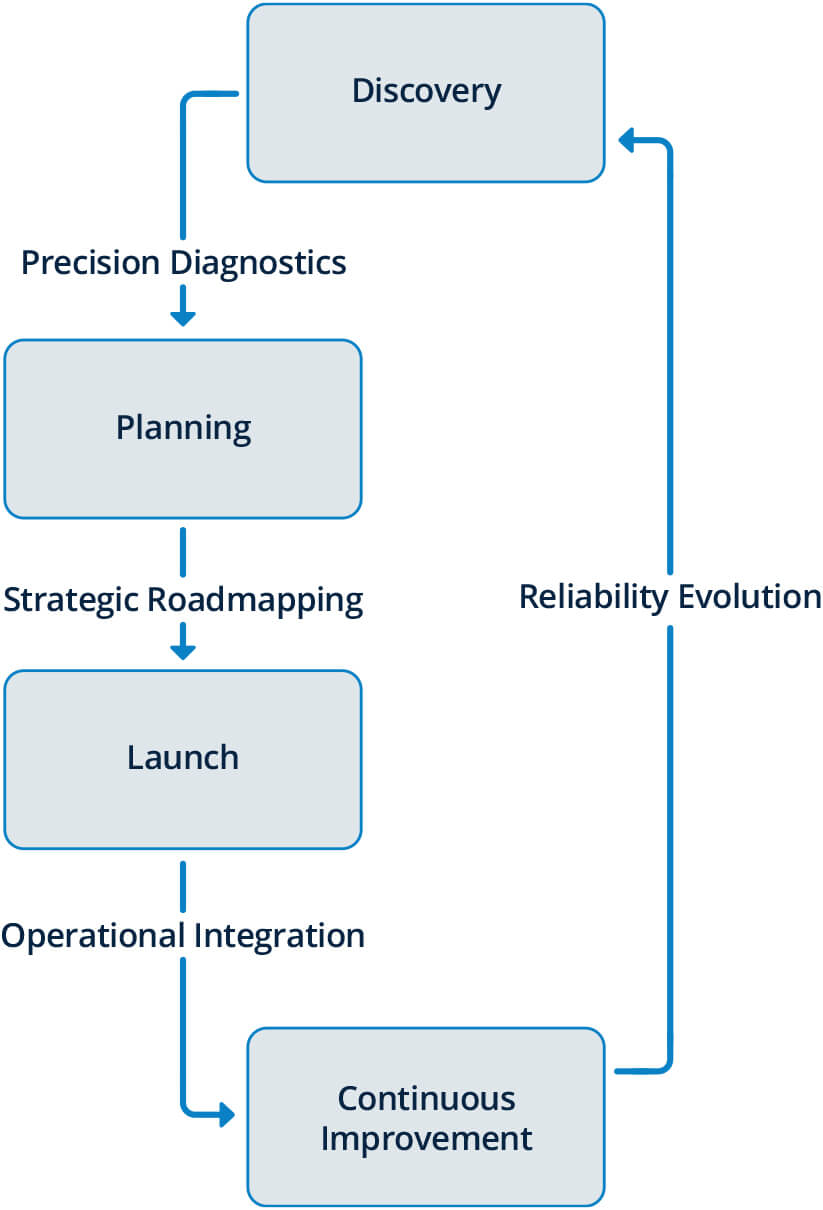

Follow our Roadmap to Improved Reliability

1) Discovery – “Precision Diagnostics”

- Conduct thorough analysis of plant operations

- Identify inefficiencies and areas for improvement

- Lay groundwork for a tailored reliability enhancement plan

2) Planning – “Strategic Roadmapping”

- Develop a customized strategic roadmap

- Select optimal Asset Management and Predictive Services

- Align solutions with operational goals for uptime and efficiency

3) Launch – “Operational Integration”

- Begin implementation of tailored solutions

- Integrate FASTRAK™ for real-time monitoring

- Enable data-driven decision-making for reliability

4) Continuous Improvement – “Reliability Evolution”

- Commit to ongoing enhancement of plant reliability

- Utilize iterative analysis for performance reviews

- Implement strategic refinements for sustained excellence

Your Data Visualization Powerhouse

Your Data Visualization Powerhouse