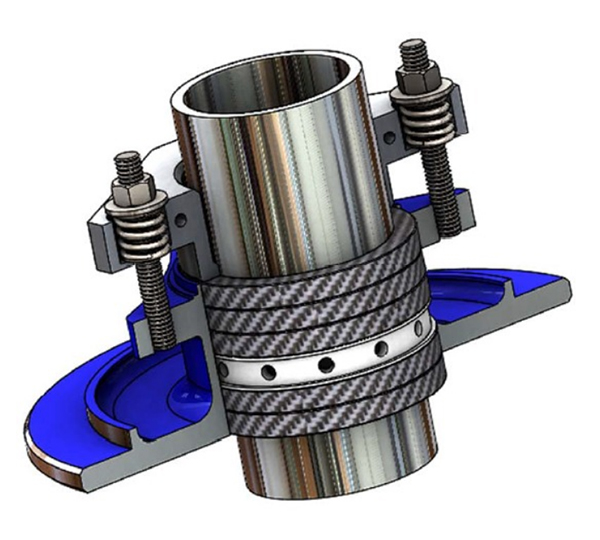

Power Gland – Spring Assisted Gland

Constant Tension, Minimal Maintenance

PowerGland can drastically reduce your operational interventions on packed rotating equipment by addressing critical issues: inconsistent gland pressure, frequent repacks, and high manpower requirements. Its spring-assisted design and high-quality alloys provide consistent gland tension on packing, significantly reduce the need for repacks, and minimize manpower requirements, enhancing operational efficiency and safety.

Power Gland

Why the Power Gland?

Features:

- Standard OEM split gland design

- Broad range of alloy options for chemical compatibility

- Designed to encapsulate compression springs

- Fits rotating equipment without modification to existing equipment

Benefits:

- Keeps constant gland pressure on packing

- Reduces the need for repacks

- Reduces manpower requirements

- Reduces packing failure from vibration and process interruptions

- Safety: eliminates the need for repacks in hazardous environments

Downloads

For more information on the Power Gland

Quote Request

The Power Gland excels in sealing these applications:

Pulp & Paper

Raw Water, Cooling Water, Chemical Handling, Thick Stock (High Consistency), Medium Consistency Stock, Green Liquor, White Liquor, Black Liquor, Waste Water Treatment, Power House

Alumina Refining

Bauxite Grinding Pumps, Caustic Cleaning Preparation, Digester Feed, Desilicator Discharge Pump, Seed Filtrate Pump, Coarse Seed Filter Feed Pumps, Seed Charge

Gold Mining

Carbon In Leach Tails, Concentrate Transfer, Cyanide Transfer, Conditioning Tank feed, Decant Water, Saline Water, Tails Thickener feed

Hard Rock Mining

Dewatering and pumping stations

Flue Gas Desulfurization (FGD)

Limestone Recirculation/Scrubber Feed, Ash Pumps, Calcium Sulfate Slurry, Gypsum Slurry, Filtrate Return

Ore Mining

Limes Pump, Concentrator Feed, Tailings/Tailings Booster pumps, Mineral sand slurry, Mineral sand concentrate

Synthetic Rutile Plant

Slurry Transfer Pumps, Acidic Slurry Transfer Pumps

Pigment Plant

Finished Slurry pump, Neutralization feed pump, Chlorine Compressors (GARO)

Industrial Processes

Sugar beets, cement fiber board, diatomaceous earth

Aggregates

Fines recovery, thickener/clarifier underflow, belt-press feed

Coal Prep/Washing

Thickener Underflow, Thickener Overflow