Seal Monitoring Systems

Primary Seal Condition Monitoring piping plans are used to control the leakage from the primary mechanical seal faces and warn users when a primary seal failure has occurred. Flexaseal produces the following mechanical seal monitoring systems according to API specifications. Our mechanical seal support systems are made in the USA at our Texas facility.

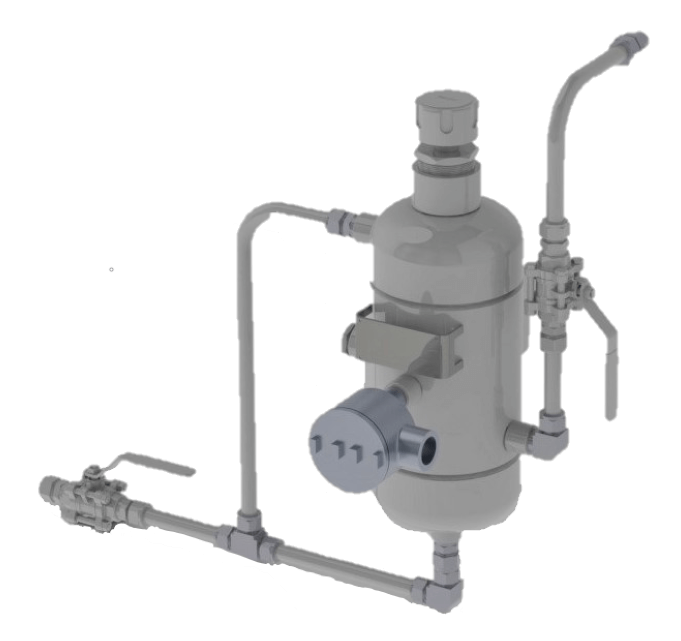

MP65 Series for API 682 Plan 65

Our MP65 system designed to be inline with API 682 Piping Plan 65 and is made to collect leakage from the primary seal. The system also warns the operator about excessive leakage from the primary seal. The API Piping Plan 65 is designed for use on generally non-hazardous process fluids that are condensing.

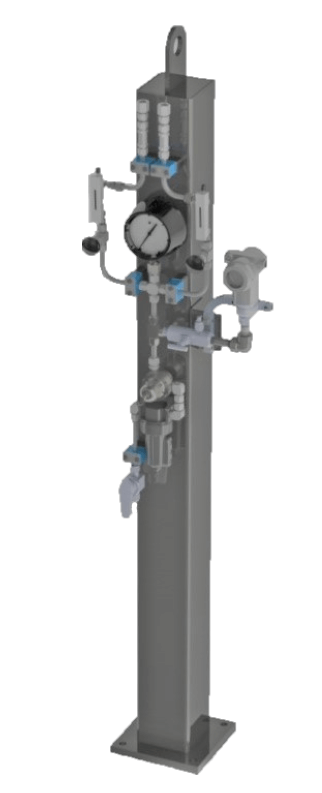

MP72 Series for API 682 Plan 72

The MP72 system is designed for buffer gas injection behind the primary seal and aligns with API 682 Piping Plan 72. The injected buffer gas sweeps and dilutes volatile emissions. The MP72 Series is also intended to operate in tandem with API 682 Piping Plans 75 or 76.

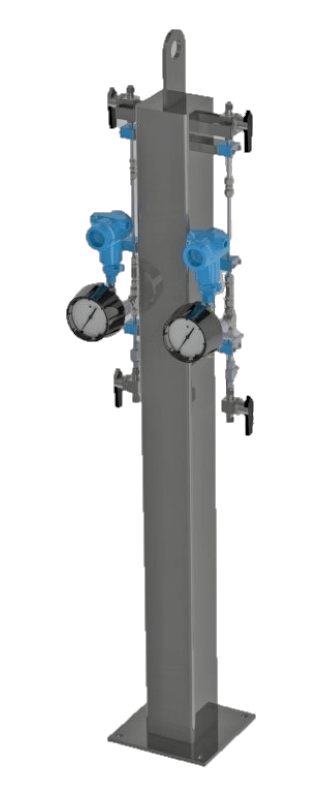

MP75 Series for API 682 Plan 75

The MP75 seal monitoring system aligns with API 682 Piping Plan 75. This model is designed to collect primary seal leakage and Plan 72 buffer gas. The system detects excessive leakage from the primary pump seal and warns the operator. The API 682 Piping Plan 75 is designed for use on process fluids that are condensing or non-condensing.

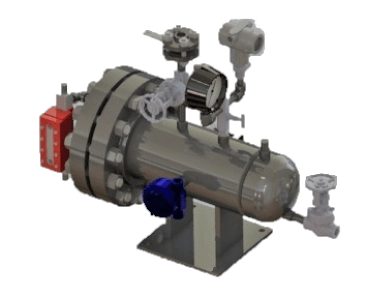

MP76 Series for API 682 Plan 76

Our MP76 system for seal monitoring aligns with API 682 Piping Plan 76. The system is designed to collect Plan 72 buffer gas as well as identify excessive leakage from the primary seal and alert the operator. The API 682 Piping Plan 76 is for use on non-condensing process fluids.