Reduce equipment failures and increase productivity with pump vibration analysis monitoring.

Vibration analysis is a predictive maintenance service that allows early problem detection in rotating machinery, such as gearboxes, fans, shafts, motors, compressors, pumps, mixers, driers, etc. Vibration analysis enables you to take maintenance action before a failure in service brings your plant to a halt.

Pump Vibration Services

Flexaseal’s CAT 3-Certified Analyst, with over twenty years of industry experience, generates a database of your equipment’s condition and monitors the data at (usually) monthly intervals specific to your plant needs.

Equipment overall vibration amplitudes and specific fault frequencies are trended over time to determine if a problem is minimal or becoming worse. Measuring specific vibration frequency, along with familiarity with the equipment being analyzed, allows the technician to diagnose and resolve the problem.

- Gear Defects

- Bent Shafts

- Motor Faults

- Misalignment

- Eccentric Rotor

- Imbalance

- Mechanical Looseness

- Lubrication Issues

- Bearing Wear

- Soft Foot

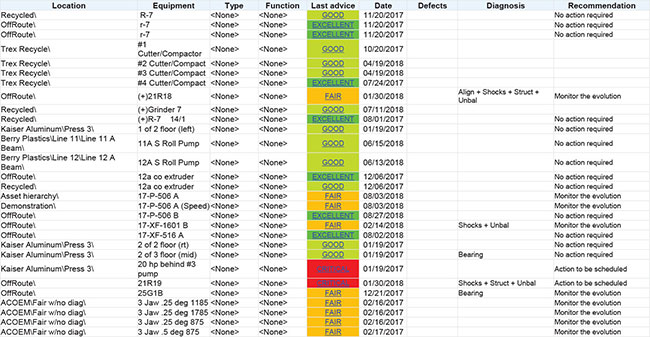

Vibration Analysis Reporting

Reports cover all industrial equipment, and whether any are, or continue to be, in an alarm status. These reports help the plant manager and maintenance supervisor maximize their mechanics’ efforts and time, thus avoiding unnecessary down time and budgeting dollars more efficiently.

- Comprehensive, Easy-To-Read Diagnostic Reports

- Delivered within Five Business Days

- Production Condition in ‘Real Time

- Equipment Performance History

- Recommended Actions

Onsite Pump Analysis

When the vibration analysis indicates: Misalignment; Out of Balance Condition; Lubrication Needs; Worn Bearings; Worn Couplings; Impeller Out of Balance, etc…

- Flexaseal can source parts and provide service technicians to install, test and certify all corrective actions.

- Flexaseal’s Lead Vibration Analysis Technician has 20 years of experience in Predictive Maintenance with Cat 3 Certification. Flexaseal has two additional Cat 1 Certified Technicians.

- For alarms indicating mechanical seal issues, Flexaseal will provide the optimal solution.

- Flexaseal’s service technicians perform 200+ laser alignments annually.

- Flexaseal can provide Oil Analysis, with an Oil Monitoring Analyst on staff as certified by the Society of Tribologists and Lubrication Engineers.

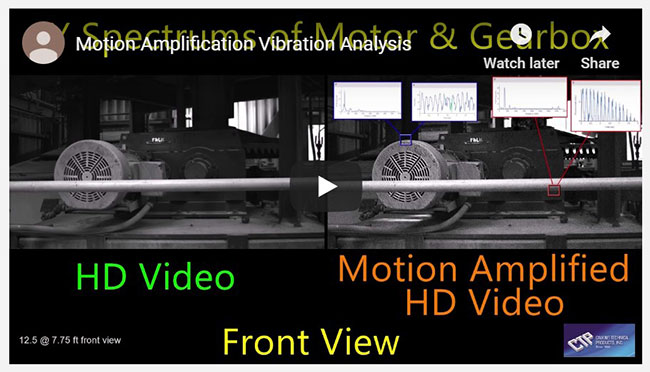

Pump Motion Amplification

Our Motion Amplification service uses very high-speed video footage of moving parts to give the most advanced method of getting to the root of vibration issues.

Predictive Maintenance Vibration Analysis (PDM)

On-going predictive maintenance services prevent more costly reactive maintenance and unplanned downtime. Instead of “Monday morning-quarterbacking” what went wrong after an equipment failure, arm your plant managers with real-time data tracking and comprehensive monitoring. A PDM service program allows plant managers to schedule downtime, labor, and materials based on the projected performance of the equipment.

- Certified Analytics Expertise

- Timely Professional Reporting

- Equipment Data Gathered at predetermined intervals

- Continuous Data Collection capabilities for highly critical equipment

- Expertise to predict, diagnose, report, and SOLVE equipment issues before they cause downtime