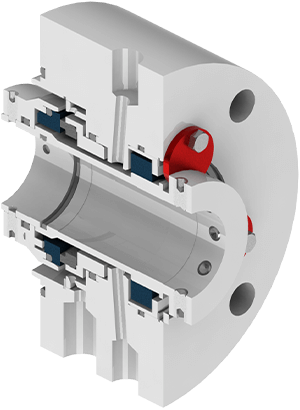

Mechanical Seal Style 58A

API Heavy Duty Stationary Multi-Spring Single Cartridge Seal

FOR HIGH PRESSURE APPLICATIONS

The Flexaseal Style 58A single cartridge seal is specifically designed for ruggedness and durability to withstand high pressure applications. Design elements include a piloted gland to positively center the seal assembly, as well as a metal-to-metal confined gland gasket which prevents blowout or extrusion of the gland packing.

The Style 58A cartridge is uniquely customizable to your specific pump and application requirements. API 682-compliant options are also available.

Features

- Stationary design for maximum face alignment

- Robust and reliable seal face drive

- Hydraulically balanced

- Dynamic O-ring moves to a clean surface

- Springs located out of product to prevent clogging and hang-up

- Rugged construction for high pressure applications

- API compliant with piloted gland to positively center seal assembly and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gland packing

- Carbon floating bushing option available

- API 682 Type A Arrangement 1 available

- Multi-point injection feature available which ensures maximum uniformity of cooling around the entire circumference of the sealing faces, thus eliminating face distortion due to uneven cooling. Ideal for boiler feed and light flashing hydrocarbon services.

- Thicker cartridge sleeve construction to eliminate distortion due to tightening of set screws

- Gland NPT connections: 1/2″ NPT for process side and 3/8″ NPT for atmospheric side to help prevent improper installation

Specifications

Operating Parameters

| Max Temp: | 550ºF (290ºC) |

| Max Pressure: | 1200 PSI (80 bar) |

| Max Speed: | 10,000 FPM (50 m/sec) |

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal Engineered Seals and Systems, LLC if in doubt.

Downloads

For more information on style 58A

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.