Vantage ANSI Mechanical Seal Product Range

The Flexaseal VANTAGE ANSI Mechanical Seal product line is our most advanced ANSI product line. These mechanical seals are designed specifically for ANSI B73.1 / 73.2 Pumps with BIG, TAPER and STANDARD bore seal chambers.

Standard Features of the Vantage ANSI Product Range Include:

- Simple Cartridge Installation

- Heavy Duty 316SS Cast Gland

- Monolithic Seal Faces for Improved Heat Dissipation

- Seal Sleeve Isolated from Process Fluid

- Multiple Connection Ports for Easy Access on a Variety of Pump Designs

- Highly Modular Design for Spare Parts Reduction by over 75% from Previous Generation

- Same Day Shipment on Most Sizes and Materials

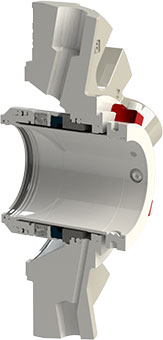

VSMS3/VBSMS3

Vantage ANSI Single Cartridge Seal

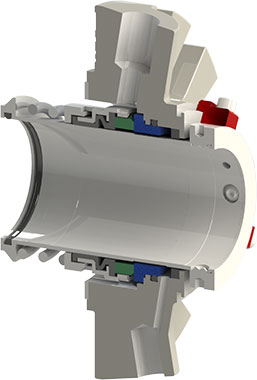

VRB3/VBRB3

Vantage ANSI Welded Metal Bellows Seal

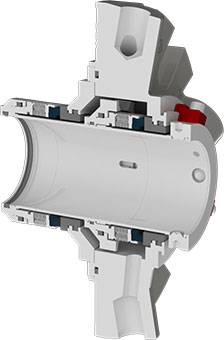

VRSS3/VBRSS3

Rotary Single-Spring Single Cartridge Mechanical Seal

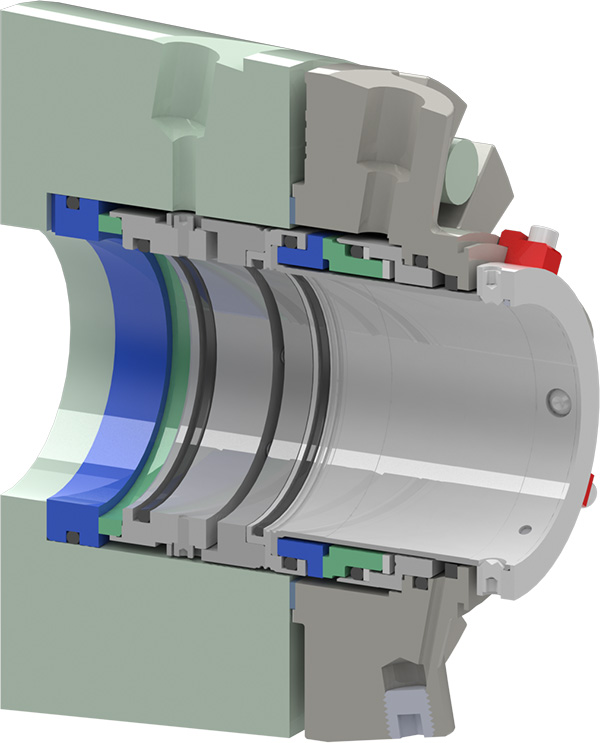

VTSMS/VBTSMS

Vantage ANSI Dual Tandem Cartridge Seal

VTRB/VBTRB

Vantage ANSI Dual Tandem Rotating Welded Metal Bellows Seal

VDRBSMS/VBDRBSMS

Vantage ANSI Industrial Hybrid Welded Metal Bellows Seal

VSSS3/VBSSS3

Stationary Single-Spring Single Cartridge Mechanical Seal

VTSE

Vantage Tandem Solids Excluding Slurry Seal

Quick Contact

For general inquiries, sales or quotes.